GE Solution Provider

- 20 Years Experience with iFix and Historian

- GE Plant Applications Experts

- Upgrade and Modernize

- VBA and Advanced GE Training

Automation software and engineering experts

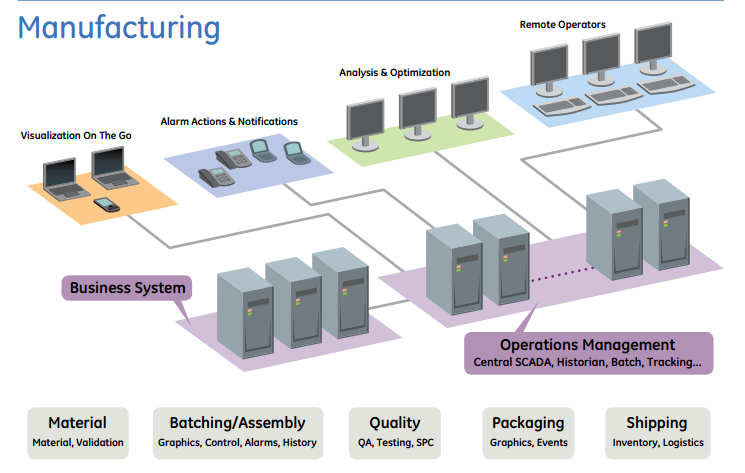

Industrial Network Systems started with Intellution in 1990 – our experienced team of automation software and engineering experts are available to assist you in the design, deployment, and implementation of your GE Proficy solutions. In addition, you can leverage INS3’s experience in manufacturing systems which and drive improvements in manufacturing results and business outcomes. We have a proven process to get you there.

GE Digital

iFix Experts

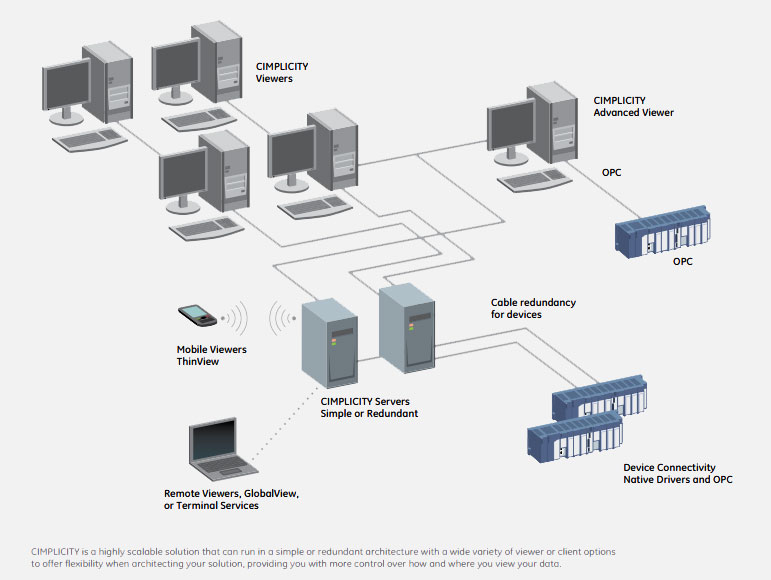

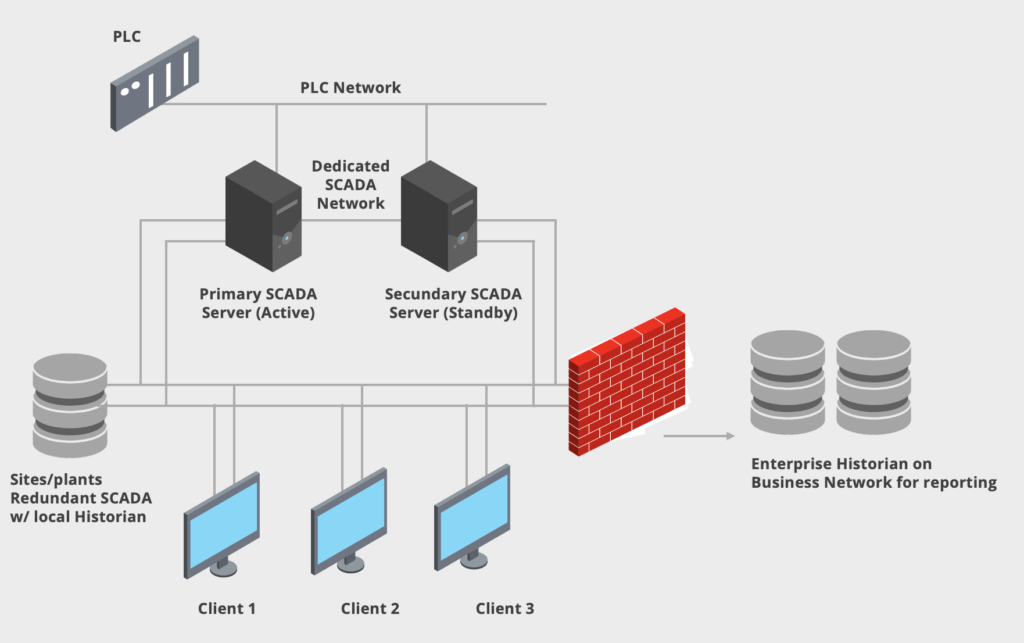

- Proficy HMI/SCADA – iFIX offers a robust SCADA engine, rich set of connectivity options, open architecture, and highly scalable and distributed networking model.

- iFix Services

- Upgrade to most recent versions

- VBA and Application Training

- Integrate to Historian

GE Digital Solution Provider Expertise

- Cimplicity Experts

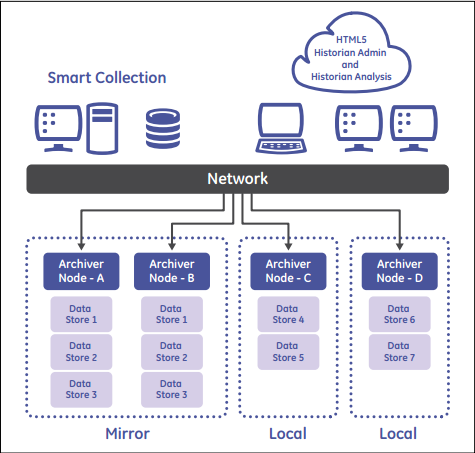

- Historian Experts

- Upgrades and Data Migration

- Reporting and Data Analysis

- Custom Calculation Collectors

- Ask about our Unlimited Clients

- GE Portal Replacement and Application Migration

- Application Migration

GE Digital Proficy Plant Applications

iFix Experts

- Enhance your Application

- Upgrade to the latest version

- Custom User Interface and Dashboards

- Integrate to your ERP, LIMs, etc.

- Microsoft Dynamics 365

- SAP S/4HANA and more

- OEE, Downtime, Quality, Production, Scheduling

No Charge SCADA Evaluation

INS3 offers a complimentary Evaluation of your Existing SCADA, HMI and/or Historian systems:

- Start with a quick 30-minute Discovery Web Meeting

- Onsite walkthrough visit (if possible)

- Our Engineers review current system details

- Create a plan to fit your needs

- Provide options with cost estimates

- Complete Project and Provide Results, like:

- Updated SCADA, OS, and Architecture

- Standardize and develop disaster recovery plan

- Implement data and alarm management

- Model-based and high-performance HMI

- Better data access for Analytics

FAQ

The reality is it depends. In some cases over the years you could run the old software on newer operating systems, but with Windows 10, it pretty much needs to be replaced or upgraded. INS has over 25 years’ experience upgrading our GE customer base, and can quickly get you budgetary numbers and options. Some of those options include moving to a new more modern architecture while saving license costs.

Since they end of life the Portal product, GE has promoted multiple “migration” paths, but none were a solution for all, and for sure none were a migration, but rather another product, that had some subset of functionality. We have migrated many of our customers to replacement based on how they used the Portal. Some who used just trending moved to Tundra Trending. Some replaced it with web code, and others another application completely. We can quickly access your use of Portal and recommend cost effective solutions from the many options.

Most of the INS Engineering team has over 15 years’ experience with the GE software lines, and are available to our customers. One of the most popular options is our Gold Support package, which gets you real world experienced technical support, as well as the ability to rent an expert on your project. It can also be used for a wide variety of services like training, small projects, or project debugging.

INS has a few certified trainers on staff, and over the many years has developed customized training for our customers to meet their exact needs. Although not a replacement for standard training classes, out ability to customize it to our customers needs has filled a void. Training can range from mentoring on a project, one-on-one training, to lecture or classroom style, with subjects that are important to the customer.

On the INS staff are some engineers who we developers of the software originally, and have over 15 years’ experience with the platform. Additionally we can augment with additional engineers as needed. Services can include support, training, upgrades, and application engineering. We can also deliver projects for our customers, and also know how to augment Plant Applications with additional applications. We also have experience upgrading, enhancing and replacing Plant Applications as makes sense.

This is a common question we are asked, and the reality is only GE knows. It has obsoleted many packages over the last decade, many have stagnated, many have new version coming out often, and they have offered new products. Some of our customers have or are investigating moving away from some of their older software packages. With our years of experience we can help our customer evaluate the risks, costs, and options.

Putting context around raw data, adding alerts, delivering trends, creating KPI’s, doing analytics, aggregating the raw data to be more valuable is the core of INS’s practice. We can help determine the best way to optimize your manufacturing utilizing the data you have. We can supply products, use the technology you have in place, and help you determine the “low hanging fruit” in the data you own today.

Ready to scale up your production?