Case Study: Predictive Quality for Peanut Butter Manufacturer

A peanut butter manufacturer faced a challenge in the form of delayed quality feedback – the final product consistency (set) could only be tested 2-3 days after production, which resulted in costly rework and waste. INS3 used AI-based quality predictive models to make real-time changes before defects occurred.

The Challenge

Delayed Quality Feedback: The peanut butter’s final consistency (“set”) could only be tested 2–3 days after filling, leading to late-stage quality failures.

High Rework & Waste: If the product did not set properly, entire batches had to be reprocessed or discarded.

Process Variability: Factors such as heat application, stabilizer levels, and material rework affected the final product quality, making it difficult to maintain consistency.

Solution

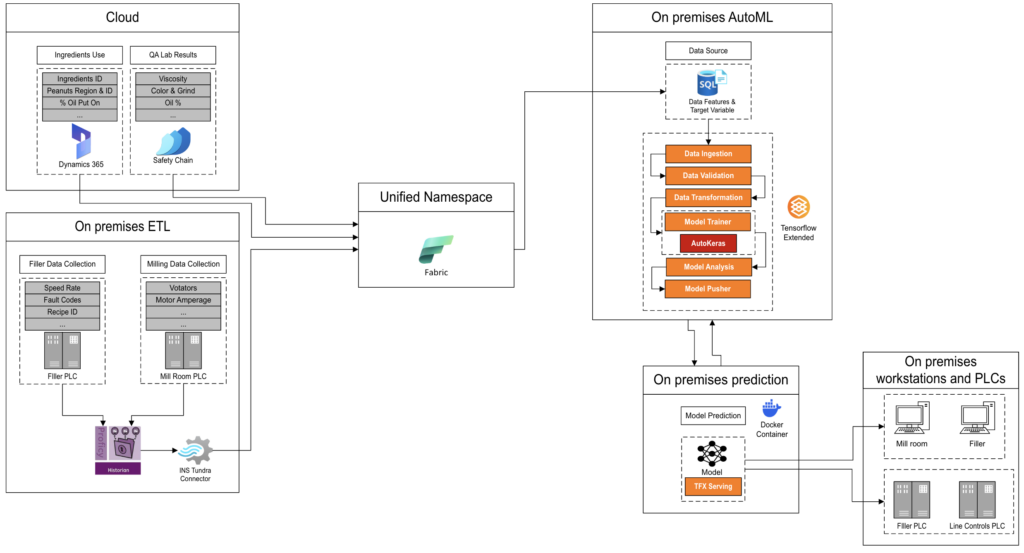

AI-Driven Predictive Quality: Machine learning models analyzed production parameters in real time to predict final product consistency before completion.

Process Optimization: AI recommendations allowed operators to adjust parameters such as heat, stabilizers, and rework inputs to ensure proper set formation.

Integrated Data Visibility: INS3 connected MES, SCADA, and lab test data to provide a unified view of quality trends and process deviations.

Results

Reduction in Waste: Improved predictive accuracy to minimize rework and disposal.

Enhanced Quality Control: Ability to adjust processes in real time, reducing product inconsistencies.

Operational Efficiency Gains: Faster identification of potential issues before production completion.

INS3’s predictive quality solution enabled proactive quality management, reducing waste and improving efficiency, with ongoing refinements to maximize ROI.

Our Customers

Join our Valued Customers

In the last 30 years, we have helped top-performing manufacturers harness Industrial Data Analytics.