Data Infrastructure

Unlock Industrial Data Architecture Excellence and Innovation with INS3

Industrial Automation and Control Systems (OT) networks are unique compared to IT networks. At INS3, we have the expertise and experience to make recommendations for Industrial Data Infrastructure that addresses your requirements and ensures its security. Connect to machines, PLCs, sensors, and other systems. Collect and store data. Deliver information when and where you need it.

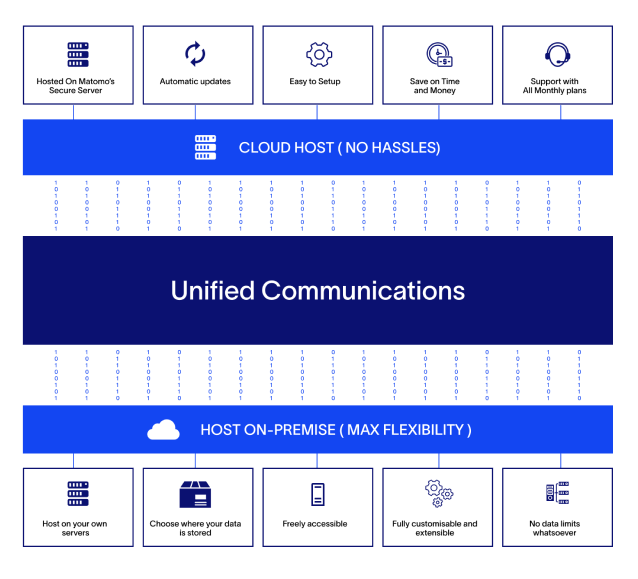

Hybrid Solutions

We can design and implement on-premise, cloud or hybrid solutions that combine the benefits of both environments for optimal performance, scalability, and security.

Improved Agility

Achieve greater business agility by leveraging the power of cloud infrastructure while still maintaining control over your critical data and applications in your on-premises data center.

Seamless Integration

We seamlessly integrate your on-premises data center and/or cloud infrastructure, providing a smooth transition and ensuring that your manufacturing operations are not disrupted.

Real-Time Monitoring

With an optimized data infrastructure for OEE, you can monitor your production processes in real-time, providing you with instant insight into how efficiently your operations are running.

Advanced Analytics

An effective OEE and Historian data infrastructure provides you with advanced analytics capabilities that allow you to identify trends, patterns and issues that may be impacting your production, leading to increased OEE over time.

Disaster Recovery

Our solutions provide built-in disaster recovery capabilities, ensuring that your critical data and applications are protected and can be quickly restored in the event of a disaster.

Assessment: Industrial Data Infrastructure

This assessment is designed to pinpoint opportunities for streamlining your data collection, analysis, and utilization processes. Our approach begins with a complimentary discovery call, followed by a free digital walkthrough. Drawing on the expertise of our professionals, INS3 conducts a thorough analysis of your current data infrastructure and suggests improvements aligned with your Industry 4.0 objectives.

Throughout our assessment, we consider both cloud-based and on-premise systems to provide a holistic evaluation of your data infrastructure. This enables us to deliver a tailored, cost-effective plan that suits your unique environment.

Our Customers

How does Master Architecture help enhance your manufacturing plan for an Industry 4.0 transformation.

In manufacturing environment, staying competitive is key. This means staying ahead of the curve in data collection, management, and analysis. With Master Architecture the integration of cutting-edge technologies such as IoT, big data, and AI into the manufacturing process becomes seamless, leading to enhanced automation, efficiency, and productivity.

A Master Architecture helps monitor and measure key performance indicators (KPIs) in real-time. This enables manufacturers to identify and address issues that impact overall equipment effectiveness (OEE), leading to reduced downtime, increased production capacity, and improved product quality.

For cloud and on-premise systems, Master Architecture ensures seamless integration. It makes data management efficient across both platforms. This enables manufacturers to leverage the benefits of both approaches. Master Architecture helps address cybersecurity concerns as well by implementing robust security measures to protect sensitive data and prevent unauthorized access. This ensures that the manufacturing process remains secure and reliable.

Our Industrial Data Infrastructure and Master Architecture services are designed to help businesses leverage Industry 4.0 technologies and take advantage of the vast amounts of data generated by modern manufacturing systems.

With our expertise in cloud, on-premises, and hybrid data infrastructure, we help you build a scalable and flexible platform that adapts to your changing needs.

Request our Industrial Data Infrastructure and Master Architecture workshop today and learn how to assess your facility readiness to start your journey towards Industry 4.0 transformation

This workshop is designed for manufacturing professionals, plant managers, IT leaders, and anyone interested in unlocking the power of industrial data infrastructure. Our workshop will help you assess your facility’s readiness for your data infrastructure transformation and provide guidance on how to enhance your manufacturing plan using cutting-edge technologies. During the workshop, our team will help you evaluate your existing data collection methods, data storage and retrieval processes, data analysis tools, and data usage across your organization. Based on this evaluation, we will provide you will be able to report that outlines areas for improvement and highlights potential benefits of upgrading your data infrastructure.

Industrial Network Systems – INS3 team will help you understand the possibilities of cloud, on-premise, and hybrid data architectures in the industrial space, whether you are just starting your Industry 4.0 journey or looking to optimize your existing setup. Our experts will guide you through the latest trends and best practices in data architecture, including the role of Master Data Architecture in enhancing your manufacturing plan. Whether you need to improve your manufacturing process efficiency, reduce downtime, or gain better insights into your supply chain operations, INS3 can help you unlock the full potential of your data.

Contact us today to schedule a workshop with INS3 and take the first step towards revolutionizing your manufacturing operations.

Our Customers

Join our valued customers

Join the ranks of top-performing manufacturers who have harnessed the power of Industry 4.0 and Industrial Data Analytics Solutions.

Why Choose INS3?

At Industrial Network Systems – INS3 we pride ourselves on our experienced team. INS3 offers expertise in both cloud and on-premise data infrastructure, providing clients with flexibility and customized solutions to meet their specific needs.

Our professional team has a deep understanding of the latest technologies, including Tatsoft, GE iFix, Ignition, Wonderware and Rockwell, and we work closely with our customers to develop tailored solutions that meet their specific needs and requirements.

Ready to scale up your production?

Contact Us Today!

When it comes to industrial processes, we understand that success is about more than just technology—it’s about getting the job done efficiently and effectively.

Contact us today to get learn more about our Data Infrastructure services.