MES Production Software & Manufacturing Intelligence

At INS3, we specialize in getting business results for our manufacturing customers with Manufacturing Execution Systems (MES), Manufacturing Intelligence Solutions, Data Collection, and Analytics solutions. We guide companies to improve with Industry 4.0, to increase quality and efficiency while reducing costs.

Why Choose INS3 for your MES Solutions?

We come with the power to transform your manufacturing system at any stage of your project lifecycle with Manufacturing Execution Systems (MES). Our expertise travelled around the globe revolutionizing companies such as 3M, Green Bay Packaging, Appleton Papers, Sargento, Algood Foods, CVS, and Unilever. With a highly savvy team, we hold a unique pedigree in the field Cloud MES software and ORR software solutions. As one of the industry veterans, our Cloud MES software includes several services:

Consulting and Engineering Services

Our deep understanding of Manufacturing Execution Systems (MES) coupled with strategic guidance for plant floor data collection, and ERP integration. We offer technical assistance to navigate the complexities of Industry 4.0.

Customized Data Solutions

We design and implement tailored information flows, integrating key components such as PLCs, Process Historians, Manufacturing Execution Systems (MES), and ERP into a cohesive system.

In-Depth Requirements Analysis

Our method entails a comprehensive assessment of your specific challenges in Manufacturing Execution Systems (MES), drawing upon our deep expertise. We utilize a unified namespace architecture to identify opportunities for improvement that deliver optimal business value.

Proof of Concept and Pilot Projects

Test the waters with our efficient pilot implementations of Cloud MES software, demonstrating the practicality and benefits of OEE tracking solutions before full-scale application.

Comprehensive MES (Manufacturing Execution System) Implementation

From initial concept to full rollout, we offer extensive support in implementing MES production software solutions, ensuring a smooth transition at every stage. Our expertise helps streamline processes and optimize efficiency throughout the entire implementation journey.

Join the Digitized Manufacturing Ecosystem with Our MES Production Software

Create a unified and cohesive information flow with MES production software and join the ranks of top-performing manufacturers who implemented MES Solutions to improve their operations.

Complimentary Assessment: Manufacturing Execution Systems (MES) and Manufacturing Intelligence Solutions

Our no-cost walkthrough and evaluation aim to judge your readiness for our MES Solutions and how Manufacturing Intelligence software can help you improve operations. Our process involves a no-cost discovery call followed by a no-cost digital walkthrough to evaluate the current state of your manufacturing business. We can also home in on one specific area or process MES against Industry 4.0 best practice.

INS3 experts will provide an evaluation of your current manufacturing systems, and identify areas for improvement, like OEE optimization, production cycles improvement, downtime reduction, and product quality improvement, all while staying within your budget.

The Value of Manufacturing Execution System (MES)

Boost Efficiency OEE

We help you achieve operational excellence through precise tracking and real-time monitoring of vital metrics with OEE tracking software. These metrics include Overall Equipment Effectiveness (OEE), downtime occurrences, waste levels, production counts, Mean Time Between Failures (MTBF), Mean Time to Repair (MTTR), and beyond. We use these metrics to uncover root issues by analyzing each operational event with its underlying causes

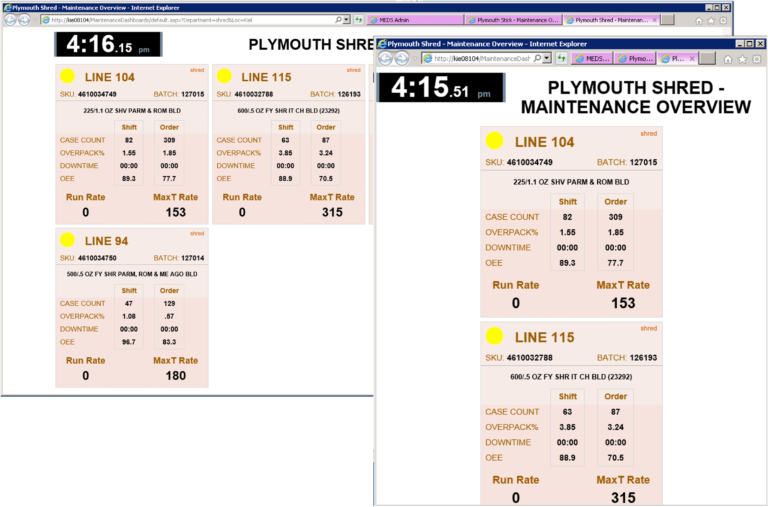

Visibility with Dashboards

Dashboards and Scoreboards summarize and analyze data by context, allowing users to correlate events and reasons to production parameters effectively. With our Cloud MES software, you can utilize standard and ad-hoc reports and dashboards for real-time decisions. Our MES production software offers comprehensive visibility into the production process, providing detailed tracking and tracing capabilities for materials, products, and equipment. This visibility is crucial for regulatory compliance and effective supply chain management.

Reduce Waste

Drive efficiency and reduce waste by gaining clear visibility into data quality and staying informed about recall information using our OEE software solutions. Integrate quality data seamlessly with process data to empower operators, enabling them to make informed adjustments that prevent waste events and minimize errors. Our OEE monitoring software ensures minimal rework and giveaway, optimizing your operations for maximum productivity.

Improve Quality

MES Solutions improves product quality through real-time trends, statistics, and notifications. It integrates data from manual and automated sources, providing a single, centralized location for process, inspection, and test information. It also supports 21 CFR Part 11 compliance and allows for attaching operator comments, specifications, recipes, and procedure documents.

ERP Integration

Integrating Manufacturing Execution Systems (MES) with Enterprise Resource Planning (ERP) enhances overall efficiency by providing real-time insights into production processes. This connectivity is one of the most invaluable information sources for manufacturing companies of all sizes. Our survivability modules help you leverage a unified namespace architecture to streamline data flow and communication with real-time interfaces and platforms such as SAP MES, Microsoft, and Oracle.

Unify Your Data

We believe in working with a data modeling structure to unify your business data. Thus, we work with the ISA-95 framework as the reference for modeling Site, Area, Line, and Cell to Edge. Once this Unified Namespace architecture is in place, it provides a powerful way to access both structured and unstructured data, coupled with the power of MES production software for efficient data management and seamless integration across your manufacturing processes.

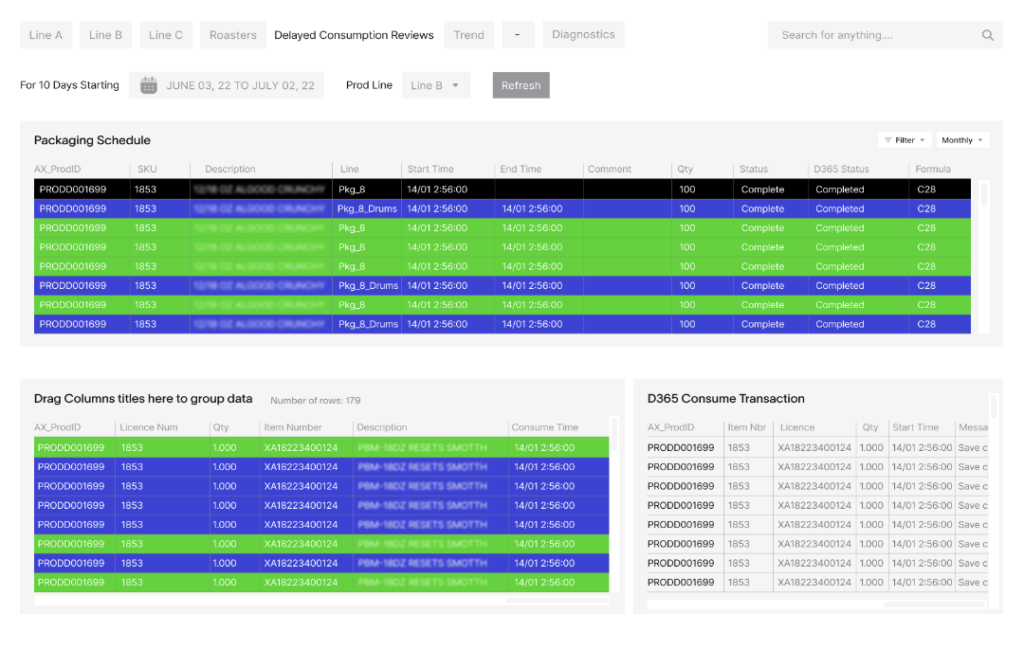

CASE STUDY: MES (Manufacturing Execution System) for Food Manufacturing

This company uses FrameworX as their factory floor software GUI application for order execution and real-time connection to their cloud-based Microsoft D365 ERP

- Use Microsoft ERP, GE MES, and Tatsoft FrameworX

- .NET GUI Application Tatsoft Frameworx, 2 Plants, 100+ Clients, One redundant pair per plant

- Tightly integrated to Microsoft ERP and MES for line efficiency, order execution, material consumption, label printing, warehouse movements, etc..

- Actual Consumption, Real time and product losses, Changeover to ERP to better estimate REAL costs.

- Power of database connectivity and interactive real-time GUI flexibility

- Plant Survivability Database

- Dashboards

- Power of connecting to PLCs

- Monitor the Quality of Peanuts using process data and ML presented in FX Trends and Reports

CASE STUDY: SAP Interface and Scoreboards with MES Software

This company communicates to SAP S/4HANA with their SCADA and MES systems and uses Tatsoft’s FrameworX to Drive Big Screen Scoreboards with KPIs

- Company is a Cheese Processor / Packager

- Products and Specifications are published to a SQL table read by SQL based MES

- FrameworX GUI and Dashboards communicate in real-time with SQL based MES Event Monitor

- Converted their SAP to S/4HANA

- Interface to SAP via XML files and SQL Linked Server

- Data includes Batch Number, Material Description, Pallet Pattern, etc.

- Pallet signal from PLC triggers insert via XML

- Beginning a project with Advanced Analytics based on data collected in GE Proficy Plant Applications

- Line Efficiency, Operator Efficiency, Giveaway

- ERP/Warehouse/MES/Historian System Coordination

FAQ

MES is a system that tracks and controls the production process, providing real-time monitoring and analytics to improve efficiency, quality, and productivity. Our MES solutions can help you increase Overall Equipment Effectiveness (OEE), reduce waste, and optimize your operations.

Our team provides comprehensive services, including consulting and engineering, customized data solutions, in-depth requirements analysis, proof of concept and pilot projects, and comprehensive MES implementation. We work with clients like 3M, Green Bay Packaging, and Unilever to deliver tailored solutions.

Our complimentary assessment includes a no-cost walkthrough and evaluation to assess your readiness for MES solutions and manufacturing intelligence. We identify areas for improvement, such as OEE optimization, production cycles improvement, and downtime reduction, while staying within your budget.

MES to ERP connectivity enhances ERP efficiency with real-time insights, allowing for better decision-making and improved supply chain management. Our solution ensures uninterrupted production during cloud connectivity loss and seamlessly connects with leading platforms like SAP MES, Microsoft, and Oracle.

Contact us today to discuss your specific needs and goals. Our team will provide customized MES solutions that drive your manufacturing facility forward, leveraging our experience and support to get the most out of manufacturing execution systems.

Ready to get started with our MES solutions?

Book Your 15-Minute Discovery Session

We provide customized Manufacturing Execution Systems (MES) and OEE software solutions that meet your specific needs and drive your manufacturing facility forward.

In just 15 minutes, we’ll align on your top business challenges and explore potential solutions.

This quick conversation helps us understand your needs, so we can recommend the right next step—ranging from a Plant Walkthrough, a pilot project, or a tailored solution designed to deliver measurable results.