INS3 helps you with Data Analytics, SCADA and MES Solutions.

Welcome to Industrial Network Systems – INS3, a trusted partner for manufacturers navigating modernization, data readiness, and digital transformation.

For more than 30 years, we have helped manufacturing leaders unlock the full potential of their operations by connecting machines, people, and systems through secure, scalable, and AI-ready architectures that turn data into measurable business value.

We understand the realities of today’s fast-paced operational environment — aging infrastructure, fragmented systems, visibility challenges, and increasing pressure to improve efficiency, cost, and quality.

That’s why INS3 delivers not only modern technology integration, but also the guidance, expertise, and phased roadmaps needed to help you transform with confidence.

30+

2300+

800+

Customers

815+

Specialized in Manufacturing Intelligence, Systems Integration & Modernization

Since our founding in 1990, INS3 has worked side-by-side with manufacturers to solve real operational challenges through the convergence of operational technology (OT) and information technology (IT).

Our work spans MES, SCADA, Unified Namespace (UNS), data historians, AI deployment, analytics, automation engineering, and ERP connectivity.

Our team specializes in:

- Manufacturing Execution Systems (MES) & Manufacturing Intelligence

- SCADA modernization and platform migrations (any SCADA → any SCADA)

- AI-ready data architectures and Unified Namespace (UNS) design

- Predictive maintenance, predictive quality, and advanced analytics

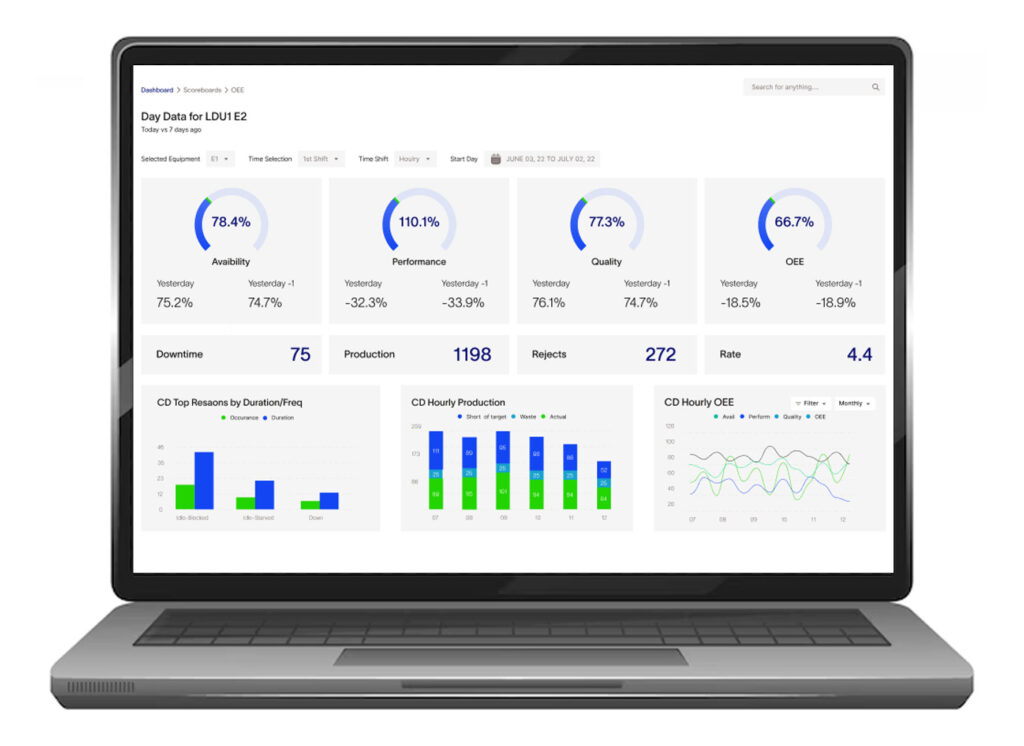

- Business intelligence and real-time visibility dashboards

- Cyber-secure OT/IT integration and network infrastructure

- IoT devices and custom manufacturing software development

We meet clients where they are — whether you need a quick modernization win, a structured roadmap, or a multi-site transformation initiative.

Our philosophy is simple: Every solution must deliver business value, not just technology.

We help our customers avoid costly implementation mistakes and build scalable foundations for long-term ROI.

Decades of experience across diverse industries — including Food & Beverage, Chemical, Pharma, Discrete Manufacturing, Energy, and Water/Wastewater — has taught us a simple truth:

Manufacturers don’t fail because of lack of data… they fail because of lack of data readiness.

INS3 brings the full spectrum of skills required to manage, modernize, integrate, and optimize industrial systems.

Experience That Delivers Results

Whether the challenge is production visibility, quality performance, downtime, or system upgrades, we bring the architecture, engineering expertise, and proven methodologies to deliver results.

Our work has helped customers:

- Increase production capacity 10–20% without new capital

- Reduce work orders by 50% using condition-based maintenance

- Improve quality through real-time visibility and predictive analytics

- Standardize SCADA systems across multiple facilities

- Modernize data infrastructure for AI and enterprise visibility

- Avoid costly downtime during ERP migrations

We have the experience, insight, and engineering depth to support your digital evolution and move your plant performance to the next level.

Our Values

Delivering Automation Solutions

Customer Focused

We focus on your real operational needs, designing solutions that deliver measurable business value and long-term success.

Innovative

We embrace modern architectures, continuous improvement, and forward-thinking engineering to stay ahead of industry change.

Reliable

We deliver results. Our team is resilient, accountable, and committed to getting the job done right in complex industrial environments.

Flexible

Every plant is different. We adapt to your processes, technology stack, and pace — meeting you where you are in your digital transformation journey.

INS3 Core Values

Our values are non-negotiable :

Customer Focused

Loyalty – Our Team is Your Team

Innovative

Resilient – We deliver results

Quality

We are committed to delivering data-driven solutions that meet the unique needs of our customers.

Innovation

We are constantly seeking new and innovative solutions to improve our products and services, and to stay ahead of industry trends.

Customer-centric

We believe that putting our customers first is key to building long-lasting relationships and achieving high business performance.

Efficiency

We aim to deliver manufacturing solutions that are efficient and streamlined, allowing our customers to improve their overall business performance and achieve greater ROI.

Flexibility

We recognize that every customer is different, and we are committed to providing flexible solutions that can be tailored to meet the specific needs of each individual client.

Continuous improvement

We are dedicated to constantly improving our products and services, and to staying up-to-date with the latest advancements in technology

Reliability

We understand the importance of automation solutions in the manufacturing and industrial sector, and we strive to deliver products and services that meet your expectations.

We are committed to delivering data center infrastructure solutions that meet the unique needs of our customers.

We are constantly seeking new and innovative solutions to improve our products and services, and to stay ahead of industry trends.

We believe that putting our customers first is key to building long-lasting relationships and achieving high business performance.

We aim to deliver manufacturing solutions that are efficient and streamlined, allowing our customers to improve their overall business performance and achieve greater ROI.

We recognize that every customer is different, and we are committed to providing flexible solutions that can be tailored to meet the specific needs of each individual client.

We are dedicated to constantly improving our products and services, and to staying up-to-date with the latest advancements in technology

We understand the importance of automation solutions in the manufacturing and industrial sector, and we strive to deliver products and services that meet your expectations.

Testimonials

What Our Customers Say

INS3 process put us on a journey of incremental investments with return at each step, without having to redo any earlier projects.

We achieved significant cost savings through reduction of water and raw material usage.

We eliminated our manual tracking of KPI's and improved the time-to-decision.

Having the information now viewable in our mobile devices, enabled timely decision-making capacity.

Achieved improvements in Quality through better reporting of issues to anticipate impact.

Getting closer to the information, allowed us to become a more viable business.

Better visibility and tracking of metrics helped to justify a new business unit for us.

We were able to meet increased demand by getting more capacity from existing machines.

About INS3

We help Manufacturing Leaders with Data Analytics, SCADA and MES Solutions.

INS3 was founded in 1990 to deliver scalable factory automation software that improves productivity and ROI from the plant floor to the enterprise. As technology has evolved, so have our solutions. Today, we implement secure, AI-ready, modern manufacturing architectures that connect every layer of your operation — from PLCs to SCADA to MES to ERP.

Our team is a family of dedicated professionals who take pride in delivering measurable results and long-term value. We combine decades of industry expertise with a modern engineering approach that emphasizes interoperability, structured data, scalability, and continuous improvement.