The AI Disconnect — Why Most Manufacturers Are Nowhere Near 'Smart'

Blog

5 Min 50 Sec Read

The Current State: Rockwell's Manufacturing Reality Check

Key Findings from the 10th Annual State of Smart Manufacturing Report

The AI Adoption Gap

Top AI Use Cases for the Next 12 Months

- 95% plan to invest in AI/ML within 5 years

- Only 20% are using smart manufacturing at scale

- 56% are still in pilot phases

- Quality Control – 50%

- Process Optimization – 49%

- Cybersecurity – 42%

- Robotics – 37%

- Logistics – 36%

The Data Efficiency Crisis

Only 44% of collected data is used effectively, highlighting a massive gap between data collection and value creation.

Most manufacturing companies aim to overcome the challenges of smart manufacturing. Among emerging small to medium-sized businesses (SMBs), 38% plan to leverage data security protocols for enhanced cybersecurity. Similarly, 41% plan to use AI and ML to reduce turnover and solve workforce issues.

Common Barriers to Adoption

Before you can use AI models successfully, you must identify areas for improvement. In the same vein, we will use the three pillars of AI implementation to achieve staggering growth

Data Fragmentation

The prevalence of data silos across manufacturing operations prevents the holistic view. But it is necessary for effective AI deployment.

Moreover, production data remains isolated from quality metrics. Simultaneously, maintenance records exist separately from operational systems. In other words, without a single source of truth, digital transformation in manufacturing becomes nearly impossible.

Manufacturing Technology Disconnect

Legacy systems present significant Smart manufacturing challenges, as they weren’t designed to meet the data-sharing requirements of Industry 4.0.

Meanwhile, the lack of OT/IT integration creates critical blind spots in operations. Incompatible protocols and the prohibitive cost of wholesale system replacement further exacerbate this issue.

Data Quality Issues

The AI apps can apply the “garbage in, garbage out” policy emphatically. Here, garbage refers mainly to ‘bad’ data sets. However, it is also important to be aware of the sources that generate inaccurate data.

Usually, bad data originates from inconsistent naming conventions, missing timestamps, and insufficient operational contexts. These major drawbacks can certainly render any advanced model ineffective.

Foundations for AI Readiness

Assess Your Current Data Landscape

INS3 begins by evaluating your existing infrastructure to understand:

- Current system connectivity and data flows

- Data granularity and whether it meets AI requirements

- Effectiveness of current data modeling and naming conventions

- Critical integration gaps are preventing comprehensive analytics

Certainly, this test highlights the kind of data you are collecting. However, it also indicates whether you are dealing with the right data or not. Consequently, you can improve predictive analytics in the manufacturing sector.

Establish a Unified Namespace

Creating a unified namespace serves as the foundation for all AI initiatives. Meanwhile, this single source of truth requires connecting critical systems.

Most importantly, SCADA system integration, MES software, ERP platforms, quality management systems, and CMMS are used to maintain a comprehensive maintenance history.

Most importantly, users have to achieve continuous improvement in architecture. Without an improved architecture, you cannot roll out the current and upcoming AI applications or recover from the challenges of smart manufacturing.

Learn how Manufacturing Execution Systems streamline production and boost ROI

Optimize Data Quality and Context

You can create contextualized data sets from raw data. However, the main requirements for that are poor machine hierarchy, product linkage, good event sequencing, and operator associations.

Subsequently, the enrichment process enables AI systems to detect seamless patterns and create effective action sequences.

Ready to Bridge the AI Adoption Gap? Discover how manufacturers are planning for AI and where they stand today.

Practical Applications of AI: Practical Use Cases

Predictive Analytics in Manufacturing

Forward-thinking manufacturers are achieving reductions of 30-50% in unplanned downtime. Most importantly, it helps them predict equipment failures 2-4 weeks in advance. Also, it translates directly to 20-30% maintenance cost reductions and significant productivity gains.

Predictive Quality

AI-powered quality systems deliver 25% reductions in defect rates while accelerating root cause analysis by 40%. Simultaneously, real-time quality predictions enable proactive adjustments to prevent defects from occurring.

OEE Software Enhancement

- 10-20% overall OEE improvement

- 15% throughput increases

- 25% reduction in changeover times

Prescriptive Maintenance

Moving beyond prediction to prescription, AI systems now recommend specific actions. To sum up, the primary requirements are optimal scheduling and parts inventory optimization. However, it should be based on comprehensive operational data.

Explore our guide to calculating and improving OEE in real-time

Your Path Forward with INS3

The Fast-Track Journey to AI Readiness

Phase 1: Discover & Assess (1-2 Months)

At this stage, you need to assess the changes in the existing data infrastructure. Likewise, you also need to identify granularity gaps and optimize the data layout. After that, you will be able to set a clear pathway for your agile transformation plan.

Phase 2: Connect & Unify (1-2 Months)

- Start with building a unified namespace architecture

- After that, connect the critical missing systems

- Above all, implement data governance standards

Phase 3: Analyze & Validate (1-4 Months)

In Phase 3, you will roll out the basic AI models. Therefore, you have to refine data collection based on the findings. After that, you can extract refined data from the AI models in manufacturing.

This stage also ensures growth in your return on investment (ROI). It also enhances your scalability through carefully planned growth strategies.

Phase 4: Scale & Optimize (Ongoing)

Expand successful use cases across facilities. After that, you can also develop advanced AI applications based on proven results.

The ROI Reality

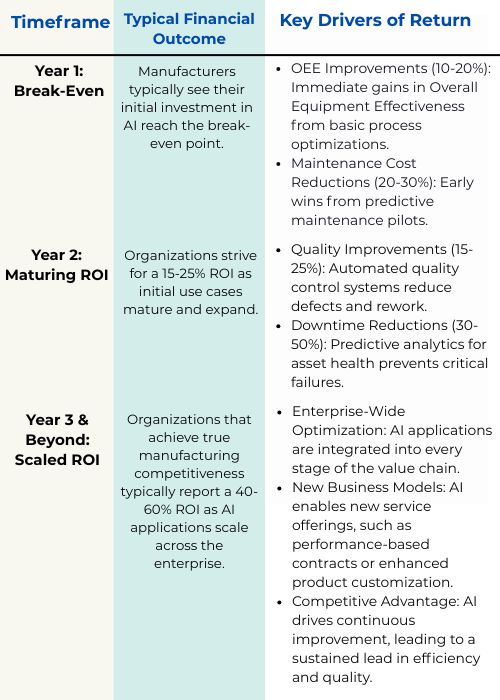

Manufacturers usually see break-even within the first year. After that, they strive for a 15-25% ROI in year two as initial use cases mature.

By year three and beyond, organizations that achieve true manufacturing competitiveness typically report a 40-60% return on investment (ROI) as AI applications scale across the enterprise.

Key metrics driving these returns include:

- OEE improvements of 10-20%

- Maintenance cost reductions of 20-30%

- Quality improvements of 15-25%

- Downtime reductions of 30-50%

Conclusion & Next Steps

To prosper in implementing AI models in manufacturing, these steps are paramount:

Bridging the AI Gap in Manufacturing

The Rockwell study reveals that success in Industry 4.0 requires more than just collecting data. Furthermore, it demands the RIGHT data, properly structured and contextualized.

Most manufacturers lack this comprehensive foundation, which explains the gap between AI ambitions and achievements.

Your Action Plan:

- Start with auditing the existing infrastructure and connectivity

- After that, identify gaps in data granularity and integration

- Most importantly, you have to partner with INS3 to build your data foundation

- Finally, pilot-focused AI initiatives with measurable ROI in manufacturing and

- Scale-proven applications enterprise-wide

Soon, manufacturers who can leverage data through AI will be at the forefront of others. They will have an exceptional competitive advantage.

Meanwhile, INS3 offers a nimble and versatile approach to realizing this transformation. So, just don’t keep hoping for an AI transition, but turn it into reality!

Agile MES: The Key to Unlocking Smart Manufacturing Success

MES is a computerized system used in manufacturing operations to track and document the transformation of raw materials into finished goods. An MES system typically manages and monitors work orders, equipment, materials, and personnel on the shop floor. The system provides real-time visibility into production processes, helps optimize manufacturing operations, and improves the overall efficiency of the manufacturing process.

Understanding OEE: The Key to Manufacturing Efficiency

In today’s competitive manufacturing landscape, improving efficiency and productivity is crucial for businesses to remain competitive. One of the key metrics used to measure manufacturing efficiency is OEE or Overall Equipment Effectiveness. In this blog, we will take a closer look at OEE and its importance in manufacturing.

How to Effectively Conduct a Legacy System Integration

Legacy system integration can be a daunting task, but it’s a necessary one for many manufacturers that rely on outdated systems to run their business. Integrating legacy systems with modern technology can improve efficiency, streamline processes, and save time and money. However, it’s important to approach the integration process carefully and methodically to ensure success.

Share on :

Keep On Reading

Subscribe to Our Newsletter

Subscribe to our weekly newsletters to get updates regarding our new production, behind the scene process of our art creation and much more.

After submitting this form you will receive an e-mail with a confirmation link that you must click to complete your request. Detailed information on processing and cancellation can be found in our privacy policy.