Headline: How to Solve Costly Plant Problems with Unified Data, MES and AI

Blog

Reduce Downtime, Optimize Quality, and Accelerate AI Readiness by Using Unified Data, MES, SCADA, UNS, and Advanced Analytics in Manufacturing

Today, manufacturers continue to face an unremitting drive for increased productivity, reduced operating costs, and increased flexibility under the growing pressures of digital transformation and Industry 4.0. Over recent years, the secret to true operational excellence has been found not just in the adoption of new technologies but in the strategic connection of MES, SCADA, and industrial IoT systems through a modern, Unified Data architecture with a Unified Namespace (UNS).

Harnessing Unified Data, real-time information, advanced analytics, AI, and robust manufacturing data infrastructure, successful organizations quickly resolve bottlenecks, reduce unplanned downtime, improve quality, and enable predictive maintenance. By walking through a proven roadmap, this article will show how leaders can take raw industrial data and make it actionable to gain a competitive advantage and tangible ROI from their analytics in manufacturing and smart factory investments.

The True Value of MES, SCADA, Historical Data, and the Unified Namespace—Wins Along the Way

A well-architected Unified Data infrastructure, with a Unified Namespace at its core, is the critical enabler in manufacturing transformation. It acts as your digital backbone, consolidating disparate machine, sensor, and system data into one real-time information model. It’s the key to connecting MES, SCADA, ERP, and IoT for maximum agility and insight.

Here’s how progressive wins are realized on the path to AI and analytics in manufacturing maturity:

MES: Unlocks workflow visibility, traceability, and immediate root-cause analysis, making bottlenecks and losses actionable.

SCADA: Provides real-time monitoring, centralized asset management, live alarms, and process variable reporting.

Historical Data: Time-series data, events, and status records are the reference point for benchmarking, continuous improvement, and predictive analysis.

Unified Namespace: Seamlessly bridges isolated systems, structures context and meaning for all plant data, and supports plug-and-play scalability as you adopt new technologies.

Wins Materialize:

- MES uncovers process inefficiencies and quality reasons, standardizes improvement.

- SCADA slashes costly unplanned downtime with instant feedback.

- Historical data provides insight into chronic losses and informs targeted interventions.

- UNS delivers a flexible, scalable Unified Data fabric that underpins everything, enabling rapid solution development, real-time analytics, and AI integration across the enterprise.

AI and Advanced Analytics—Maximizing Value When the Foundation Is Set

The value of AI in manufacturing is only unlocked if the foundational systems provide broad, high-quality, contextualized Unified Data, which is exactly what UNS, MES, and SCADA deliver. That’s where AI thrives to drive smarter decisions and operational excellence.

AI as a Force Multiplier:

- Predictive Maintenance: AI models anticipate failure before it happens. Downtime is minimized, and expensive emergency maintenance is avoided.

- Process Optimization: Machine learning analyzes the relationships across Unified Data sets to find parameter changes that yield energy savings, efficiency gains, and reduced scrap.

- Quality Analytics: Advanced algorithms identify anomaly trends and emerging issues before they cause defects or customer complaints.

With a Unified Namespace, each new analytic, AI model, or dashboard draws from the same Unified Data context for faster implementation and better results.

Step-by-Step—INS3’s Strategic Approach to Solving Costly Problems

Technical executives understand that transformational performance requires disciplined execution. INS3 supports manufacturers through:

Step 1: Focus on the Most Significant Problem

Begin with a high-impact cost or process constraint, quantify the dollars or hours lost, and target the bottlenecks or risks that matter most.

Step 2: Audit and Map Data Sources

Inventory MES events, SCADA tags, and historical stores. INS3 architects a Unified Namespace that connects everything with context and clarity, creating a clear Unified Data model.

Step 3: Data Integration and Connectivity

Bridge cloud, on-premise, and hybrid environments to ensure all assets and information flow into the UNS. Get a real-time, centralized view of engineering, operations, and analytics in manufacturing.

Step 4: Apply Targeted Analytics and AI

Deploy visualizations, diagnostic models, and machine learning applications directly from UNS. Go from basic dashboards to robust, actionable insights and recommendations.

Step 5: Operationalize Actions

Automate resolutions where feasible, maintenance scheduling, process tweaks, and quality checks, while empowering plant teams with real-time, actionable prompts from analytics.

Step 6: Validate and Scale Results

Track savings and outcome improvements versus historical baselines. Refine and scale processes to additional problem areas; UNS ensures rapid expansion and adaptability for new projects and solutions.

INS3—Your Partner in Data Foundation, UNS Integration, and AI Readiness

INS3 engineers help manufacturers design, deliver, and continuously improve the full Unified Data ecosystem required for operational excellence:

- Expert MES & SCADA Integration: Tatsoft, Ignition, Wonderware, Rockwell, Aveva and more.

- Unified Namespace Architecture: Delivers real-time, cybersecure, context-rich data connectivity.

- Analytics & AI Enablement: From historical and descriptive reporting to advanced, predictive, and prescriptive analytics.

We prioritize measurable wins at every stage—from process clarity, downtime prevention, and quality improvement using MES/SCADA and UNS—to scalable deployment of AI for predictive and cost-saving outcomes. Every solution is tailored to your systems, goals, and plant realities.

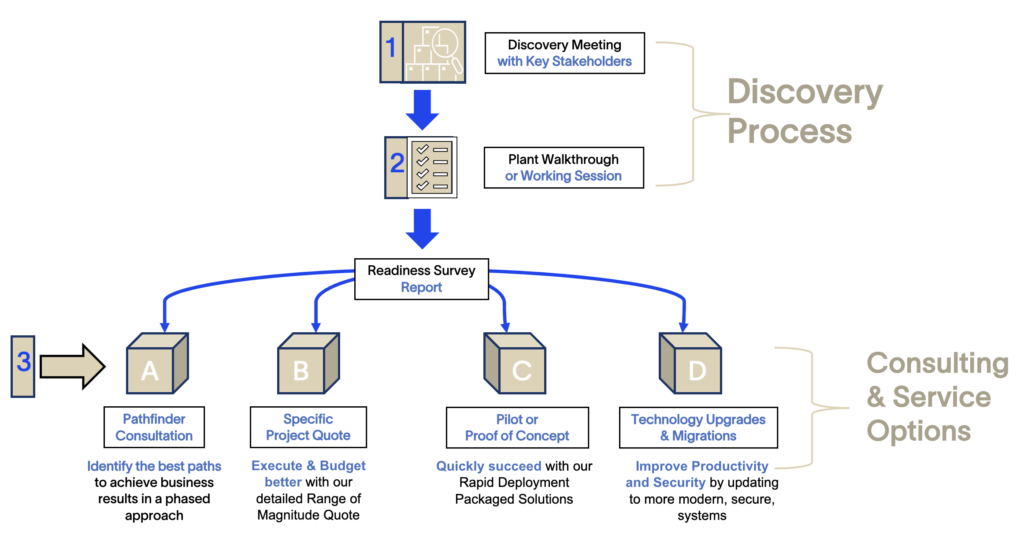

Accelerate Your Data-Driven Problem Solving

Your mission: deliver results and future-proof operations. INS3 can start your journey with a free Industrial Data Architecture Review or concise executive discovery session.

In one session, we will:

- Clarify your most costly operational challenges.

- Audit and prioritize the data landscape: MES, SCADA, IoT, UNS.

- Map transformation steps for actionable analytics in manufacturing and AI.

For leaders ready to act, we offer pilot engagements, UNS and system integration, analytics dashboards, predictive maintenance, or process quality initiatives with immediate and defendable business impact.

Contact INS3 today to put your Unified Data to work, solving the problems that matter most. Scale from foundational wins to enterprise-wide operational transformation—with a Unified Namespace leading the way.

Agile MES: The Key to Unlocking Smart Manufacturing Success

MES is a computerized system used in manufacturing operations to track and document the transformation of raw materials into finished goods. An MES system typically manages and monitors work orders, equipment, materials, and personnel on the shop floor. The system provides real-time visibility into production processes, helps optimize manufacturing operations, and improves the overall efficiency of the manufacturing process.

Understanding OEE: The Key to Manufacturing Efficiency

In today’s competitive manufacturing landscape, improving efficiency and productivity is crucial for businesses to remain competitive. One of the key metrics used to measure manufacturing efficiency is OEE or Overall Equipment Effectiveness. In this blog, we will take a closer look at OEE and its importance in manufacturing.

How to Effectively Conduct a Legacy System Integration

Legacy system integration can be a daunting task, but it’s a necessary one for many manufacturers that rely on outdated systems to run their business. Integrating legacy systems with modern technology can improve efficiency, streamline processes, and save time and money. However, it’s important to approach the integration process carefully and methodically to ensure success.

Share on :

Keep On Reading

Subscribe to Our Newsletter

Subscribe to our weekly newsletters to get updates regarding our new production, behind the scene process of our art creation and much more.

After submitting this form you will receive an e-mail with a confirmation link that you must click to complete your request. Detailed information on processing and cancellation can be found in our privacy policy.