How a Peanut Butter Manufacturer Dodged Disruption & Saved Thousands/Hour by Moving Their ERP to the Cloud

Transitioning to a cloud-based Enterprise Resource Planning (ERP) system requires overcoming the challenge of keeping production running smoothly during ERP connectivity issues. This shift demands detailed planning and strategic execution to ensure uninterrupted production, even when access to the cloud-based ERP is temporarily lost. It highlights the need for a resilient operational plan that maintains productivity despite potential cloud connectivity interruptions.

Avoided event disruption migration

$Thousands/hour

lost revenue savings

With the requirements of the cloud implementation realized, the manufacturer was able to avoid loss of revenue from lost connection to the ERP. This cost savings translated to tend of thousands of dollars / hour in the event of disruption. Production could fully operate in the absence of this connectivity.

The Challenge

A transition to a cloud-based ERP (Enterprise Resource Planning) system highlights critical considerations for this manufacturer and businesses that rely on continuous, uninterrupted operations. The company’s concerns about moving to a cloud-based solution are common among manufacturing entities, especially those that operate 24/7 and have a highly automated production environment. The primary worries included:

- Cloud Unavailability: Concerns about the potential for the cloud-based ERP system to be unavailable, which could disrupt the customer’s highly automated and continuous production processes.

- Connectivity Issues: The risk of encountering connectivity problems that could prevent the customer from accessing the cloud-based ERP system, leading to operational downtime or inefficiencies.

- Planned Outages for 24/7 Operations: The need to manage and mitigate the impact of planned outages on operations, which run 24/7. This requires constant access to the ERP system for production management and control.

- Operational Continuity: Ensuring the capability of maintaining operational continuity and production efficiency, with a particular focus on how to keep the production environment running smoothly without access to the cloud ERP system for several days if necessary.

VP Operations

One of the risks of moving ERP to the cloud is at times it will be unavailable for maintenance or other issues. INS Survivability Database enables us to run production during any of these losses of connection to ERP, which is a requirement for a 24/7 facility.

The Solution

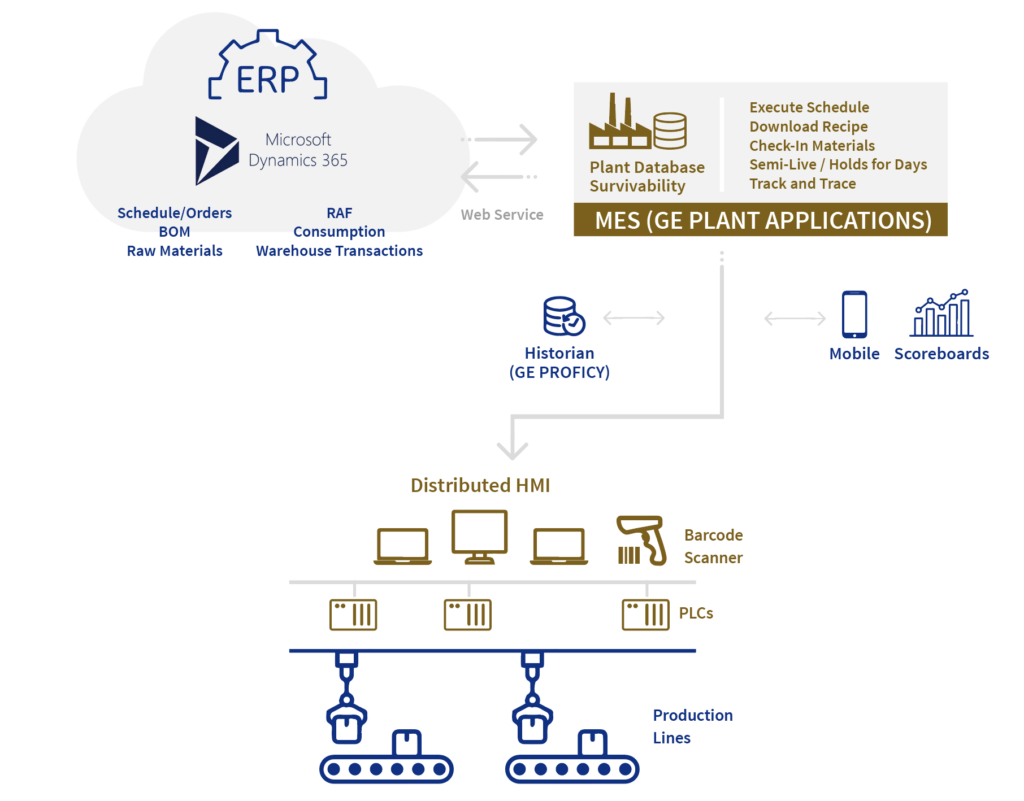

To solve the challenges that came with moving their ERP system to the cloud, the manufacturer made some upgrades to their Manufacturing Execution System (MES). They added features to help adjust production needs, like changing the order of production or using different ingredients, while keeping track of everything properly. This was a big task, especially because they had to change how they organized their Bills of Materials (BOMs), work with a new warehouse system (WMS), and start some new services. All of this needed a lot of testing before it could start working. The challenge was even bigger because the COVID-19 pandemic meant everyone had to work from home.

The solution also involved using Electronic Data Interchange (EDI) to handle customer orders. These orders were sent to the cloud, and then production plans, including what materials were needed and how much, were sent to the production team. The MES system was key in using up raw materials correctly, keeping an eye on the production process, making sure the final products were good, and keeping track of finished goods.

The MES system worked closely with the new warehouse system. It helped use raw materials efficiently and managed finished products, making sure everything could be traced back if needed. This was important for recalling products if there was ever a problem. Quality, Maintenance, and many other systems were also integrated into the architecture.

This whole approach made sure that our customer could keep their operations running smoothly, 24/7, even with the move to a cloud-based ERP system and the challenges of working remotely during a pandemic.

Highlights of the Solution:

- Enhanced MES Features

- EDI and Cloud Integration

- Efficient Use of Materials and Quality Control

- Improved Operational Continuity and Sustainability

The Results

By upgrading to a cloud-based ERP system and enhancing MES, the customer achieved significant business improvements. Including:

- 10-15% increase in first-pass quality,

- 10% reduction in product downgrading,

- 10-15% savings in utilities,

- 5% decrease in waste,

- substantial reductions in schedule disruptions.

The implementation enabled the Peanut Butter Manufacturer to avoid potential revenue loss from connectivity disruptions, translating to savings of thousands of dollars per hour during such events.

INS3 Tip

Not sure where to start? Start by collecting the time and event series data. Analytics run best with a lot of correlated data and you never know the variable that will be the most important. Or if you’ve got questions, let us help.

Start your Digital Journey Right Now

No matter where you are in your Digital Transformation journey, we can help you establish next steps with our proven Pathfinder Process, where we analyze people, processes and technology to determine your plant rediness for digital transformation, resulting in a plan with a budget.