Cutting Work Orders by 50%: The Secret Behind MSD's Game-Changing Asset Maintenance Overhaul with INS3!

The Metropolitan Sewer District (MSD) has revolutionized its maintenance strategy by moving from a conventional time-based approach to a dynamic, data-driven model with INS3 integration. This shift has not only streamlined processes through real-time data and predictive analytics but also slashed work orders by nearly 50%. The transformation has delivered immediate cost savings and set the stage for continuous improvements, showcasing the significant impact of technology on operational efficiency.

From Data Rich, Business Value Poor to

50%

reduction in the amount of work orders

Condition-Based Maintenance led to a reduction in costs, and Predictive Maintenance led to a reduction in risk.

Technologies Involved: CoreM, Historian, Maximo CMMS

The Challenge

For many years the District was doing preventative maintenance, and in fact, had dashboards showing compliance with the time-based preventative maintenance:

- Over-reliance on Time-Based Preventative Maintenance: The District revolutionized its maintenance strategy by transitioning from a traditional time-based approach to an advanced, data-driven unified namespace (UNS) model with INS3’s integration. This innovative shift streamlined process transformation not only delivered immediate cost savings but also laid the groundwork for ongoing improvements, highlighting the significant role of technology in boosting operational efficiency.

- Unlock Your Data’s Potential: Harness the power of SCADA Historian and CMMS data to transform your maintenance strategy. Uncover patterns, predict failures, and optimize timing with our advanced analytics. Make informed decisions, reduce downtime, and boost operational efficiency.

- Inefficient Use of Sensors: Available sensors were not fully integrated or utilized to monitor equipment performance in real-time. This data is crucial for moving towards a predictive maintenance model.

- Asset Mobility Issues: The challenge of tracking movable assets complicates data analysis, as maintenance records and sensor data cannot be accurately linked to specific assets when they are frequently relocated.

Division Manager

Metropolitan Sewer District

We had a desire to improve how we maintained our assets, and in partnership with INS we were able to identify key opportunities for improvement, and by utilizing our existing infrastructure, we able to see significant reduction in the amount of work orders generated, and can now justify investments in adding sensors to improve our condition based maintenance with the existing software tools. The INS system improves Maximo by delivering real data and alerts

The Solution

Revolutionize your maintenance strategy with the seamless integration of INS3 CoreM Software into your existing systems. This powerful combination brings together advanced aggregation, detection, and analytics capabilities, setting a new standard for accurate and cost-effective maintenance operations.

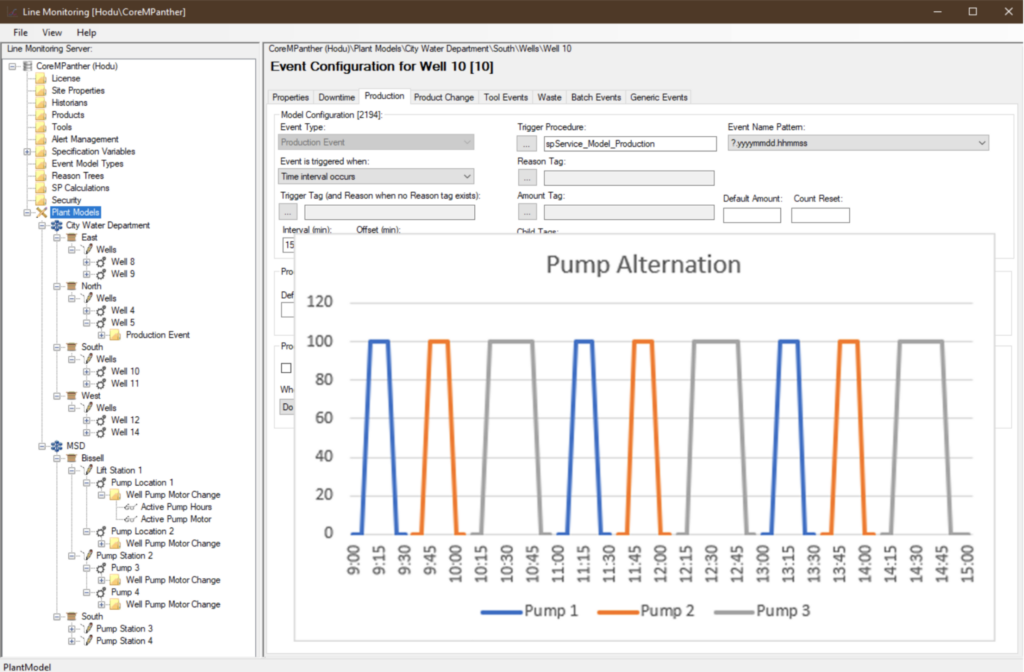

At the heart of our solution is the innovative INS3 CoreM’s asset structure, meticulously designed to reflect your existing equipment configurations and established namespaces. This model not only tracks the precise location of each asset—whether in repair, in operation, or elsewhere—but also ensures seamless identification across CMMS, SCADA, and other systems. With real-time alerts and comprehensive event history tracking, stay ahead of maintenance needs like never before.

Our approach further enriches your strategy by correlating the operational conditions of pumps with asset models, aggregating critical data over time. By capturing run-time, vibration data, and other essential metrics, we lay the groundwork for a knowledge base that adapts as assets move and conditions change.

The culmination of our integration is a smart alert system, driven by specific business rules to automatically notify Maximo when maintenance thresholds are met. This not only triggers timely work orders but also ensures maintenance efforts are precisely aligned with the real needs of your equipment. Experience unprecedented operational efficiency and cost savings with our tailored, predictive maintenance solution.

Highlights of the Solution:

- Modelling the Enterprise and Assets

- Dynamic connection to real-time and Historical Data in context (location)

- Seamless Communications to multiple systems

- Flexible and Scalable with no rip and replace.

The Results

The District was able to accomplish close to a 50% reduction in the amount of work orders required on the assets included in the pilot. This success demonstrated the effectiveness of the implemented solution and also set the groundwork for future expansions for further improvements:

- Condition-Based Maintenance – reduction in costs

- Predictive Maintenance – reduction in risk

- Prescriptive Analytics – optimized

SCADA Supervisor

This is just the start of optimizing our maintenance plan. The tools utilized will help in a continuous improvement journey of saving money with little to no additional investment

INS3 Tip

Not sure where to start? Start by collecting the time and event series data. Analytics run best with a lot of correlated data and you never know the variable that will be the most important. Or if you’ve got questions, let us help.