Engineering and Consulting Services

Your Trusted System Integrator – Leveraging Industry 4.0

Discover more value from your plant floor operational data with INS3 and our Systems Integration services. Whether we’re modernizing your Industrial Data & SCADA infrastructure or providing innovative Data Analytics for efficiency and innovation, we specialize in integrating IT and OT seamlessly. Let’s streamline and secure your industrial operations together.

Our Services

Your System Integrator to Leverage & Modernize Your Existing Systems

Together we align your operational digital transformation with Industry 4.0 by modernizing and choosing innovative solutions and technologies to drive your performance. Industrial Network Systems – INS3 provides a phased path forward and gives you the freedom to innovate incrementally.

Unlock the power of data transformation and streamline your operations with our automated solutions. Say goodbye to manual data entry and paper clutter as we convert your raw data into actionable insights, delivering tangible business value.

Data Infrastructure

Design services to connect to your machines, collect data, store the data, and deliver information to the appropriate people, or systems.

MES & Manufacturing Intelligence

Implement data driven systems that solve manufacturing issues like quality, efficiency, downtime, scheduling, consumption and connects to ERP and more.

OT Cyber Security

Protect your industrial OT devices with purpose-built security. INS3 provides protection for any OT device running any IP protocol with our industrial cyber security services.

Data and SCADA Modernization

Upgrade and migrate existing systems, get them on new servers and OS’s, and move to a more modern architecture.

Data Analytics

Gain a competitive edge by leveraging Big Data, IIOT, and Industrial Data Analytics for manufacturing.

Consulting and System Integration

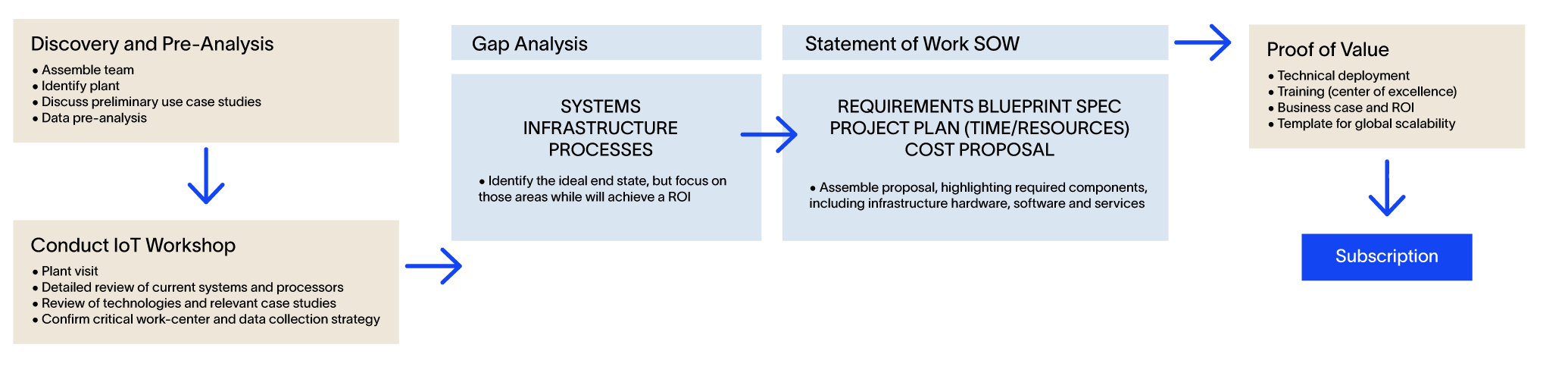

We use our proven Pathfinder approach to identify where opportunities exist to leverage your plant floor systems and identify gaps keeping you from meeting your operational goals. Begin your journey with a complimentary onsite Plant Readiness Assessment.

Our Services

From Legacy to Innovation – Experience a seamless integration with us!

We at Industrial Network Systems – INS3, pride ourselves on the ability to take any existing legacy systems and bring them to the next level. With our extensive expertise, we can seamlessly integrate your old industrial systems with new, modern technology. We understand the complexities,risk and high cost associated with taking down a legacy industrial system. That’s why we specialize in building on your existing infrastructure and we acquire the experience needed to innovate with the old and transform for the new. We offer cost-effective solutions that minimize disruption to your operations while maximizing the benefits of new technology. Let us take your Industrial Systems to the next level!

Connect

Rich expertise in connecting to any device on your production floor, from machines and Programmable Logic Controllers (PLC) to sensors and other industrial equipment.

Store

Connect and then collect real-time data combining time-series data with process and production events. We enable efficient data storage in a centralized process data historian, SQL, or data lake.

Analyze

Employ analytics and machine learning to gain valuable insights. Monitor equipment performance, detect anomalies, and leverage Overall Equipment Effectiveness (OEE) measures to gain a comprehensive understanding of production efficiency.

Request our Industry 4.0 Workshop and learn the path to Industrial Digital Transformation success

One of the key challenges in implementing Industry 4.0 is the need to manage and integrate data from multiple sources and systems. In the context of Industry 4.0, a unified namespace can help to ensure that data is consistent and accurate across different parts of the manufacturing process. Our workshop is designed to provide you with a comprehensive overview of the latest trends and technologies in the Industry 4.0 landscape, including the Industrial Internet of Things (IIoT), big data analytics, machine learning, and more. You’ll learn about the benefits of Industry 4.0 and how it can help you streamline your operations, increase your competitiveness, and drive growth.

So don’t wait any longer – request our workshop today and start your journey towards Industry 4.0 transformation.

Experience Counts

Boost Success, Minimize Costs

INS's team of engineers uses practical and efficient technology to deliver optimized results. Our proven solutions lead to increased profitability and reduced operational expenses.

Enhance Operational Efficiencies

We understand your needs and goals to identify opportunities for improvement. With a focus on peak efficiency, we ensure every system in your plant operates at its best, positively impacting your bottom line.

Mitigate Risks

Automation and operational software are critical for consistent improvement, proactive measures, and issue mitigation. By automating functions, we ensure minimal downtime and peak efficiency for your production.

Optimize Capital Investment

From maintaining consistency and increasing efficiency to eliminating risks and maximizing security, our proven processes deliver fast returns on your investment. Our solutions cut operational costs, increase productivity, and boost profit margins.

Our Customers

Join the Ranks of these World-Class Industry Manufacturers

Commitment to the highest quality production standards, a broad expertise, and a genuine strive to help our clients achieve their digital transformation.

READY TO a N0-Cost Discovery Call with one of our experts?