We Accelerate Your Growth with Our Industry Specific Solutions

We are your reliable advisor specializing in providing innovative and efficient Industry 4.0 solutions for a wide range of sectors. We leverage our expertise in various technologies and engineering disciplines to design, implement and support solutions that meet and exceed the unique needs of our clients. Industrial Network Systems – INS3 works with you to improve efficiency, reduce costs and stay ahead of the competition with our systems integration services and leading-edge solutions.

Food & Beverage and CPG

Our solutions help food and beverage manufacturers to optimize their production processes, reduce waste, improve product quality and safety, and increase throughput. We also specialize in helping clients comply with regulatory requirements related to food safety and traceability.

Chemical & Industrial

Energy & Power

Our solutions help Energy and Power companies to optimize their operations, reduce costs, and improve reliability. We specialize in the design and implementation of control systems, data analytics, and asset management solutions that help our clients achieve their business objectives.

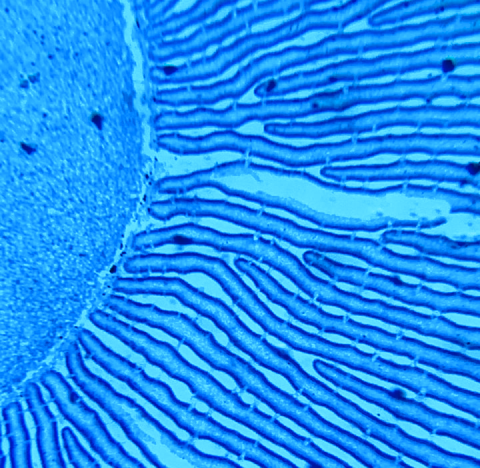

Pharmaceutical & Life Sciences

With over 30 years of experience in the pharmaceutical, biopharmaceutical, and medical devices industries, we offer solutions that enable you to accelerate and improve manufacturing efficiency, and ensure regulatory compliance. Our expertise in automation software, data analytics, and validation ensures that our clients stay ahead of the competition while meeting the highest standards of quality.

Water & Wastewater

We help water and wastewater utilities to optimize their operations, reduce costs, and improve water quality. We specialize in the design and implementation of cyber security systems, SCADA systems, asset monitoring, and data management solutions that enable our clients to operate more efficiently and effectively and meet regulatory compliance.

Manufacturing and Discrete

Food & Beverage, CPG

Our solutions help food and beverage manufacturers to optimize their production processes, reduce waste, improve product quality and safety, and increase throughput. We also specialize in helping clients comply with regulatory requirements related to food safety and traceability.

Chemical and Industrial

We work with chemical and industrial manufacturers to optimize their production processes, reduce energy consumption, and increase product quality and consistency. Our solutions leverage advanced technologies such as sensors, process control systems, and data analytics to help our clients achieve their business objectives.

Energy - Electricity, Oil, and Natural Gas

Our solutions help energy and power companies to optimize their operations, reduce costs, and improve reliability. We specialize in the design and implementation of control systems, data analytics, and asset management solutions that help our clients achieve their business objectives.

Pharmaceutical and

Life Sciences

Our solutions help energy and power companies to optimize their operations, reduce costs, and improve reliability. We specialize in the design and implementation of control systems, data analytics, and asset management solutions that help our clients achieve their business objectives.

Water/Wastewater

Our solutions help water and wastewater utilities to optimize their operations, reduce costs, and improve water quality. We specialize in the design and implementation of control systems, SCADA systems, and data management solutions that enable our clients to operate more efficiently and effectively.

Manufacturing

We work with a wide range of manufacturing companies to design and implement customized automation and control systems that help them increase productivity, reduce costs, and improve quality. Our solutions are designed to meet the unique needs of each client and are scalable to accommodate future growth.

Improve your operations with Data Driven solutions and System Integration.

Downtime and OEE

Maximize machine uptime and optimize your operations with OEE solutions that supercharge efficiency and minimize downtime.

Quality Management

Enhance quality control by continuously monitoring and swiftly identifying real-time issues to prevent potential escalation, particularly in the context of food manufacturing where precision is paramount.

HMI / SCADA

Modernize and optimize your current SCADA and HMIs as the foundation for real-time data. Get more out of your existing systems.

Modernization

Modernize your legacy systems to improve your manufacturing operations, we can upgrade your existing systems to provide a path forward.

Data Historian

Experience the benefits of a time-series process data historian – a software solution that offers high-GRANULARITY, long-term data storage capabilities AS THE BASIS FOR ANALYTICS

Cyber Security

Transform your business and manage risk with INS to protect against cyber threats. Our industrial cybersecurity services are focused on OT networks and OT devices, regardless of the IP protocol in use.

ERP Interface

Integrating your ERP system with your manufacturing offers significant benefits. This two-way interface streamlines operations, reduces costs, boosts quality control, and improves traceability – all in real-time.

Regulatory Compliance

We provide comprehensive compliance solutions through secure and reliable data collection designed to keep you protected. Data collection solutions are FDA and 21 CFR part 11 compliant.

Asset Management & Maintenance

We help you define, implement, and optimize the use of your machine assets, reduce downtime, and increase productivity.

Analytics

Our analytics solutions help you identify opportunities to optimize production, improve quality and reduce costs. We are experts at data collection from the manufacturing edge to the cloud and all points in between.

Maximize machine uptime and optimize your operations with OEE solutions that supercharge efficiency and minimize downtime.

Enhance quality control by continuously monitoring and swiftly identifying real-time issues to prevent potential escalation, particularly in the context of food manufacturing where precision is paramount.

Modernize and optimize your current SCADA and HMIs as the foundation for real-time data. Get more out of your existing systems.

Improve your manufacturing operations by digitizing your business and optimizing investments in operational technology and services.

Experience the benefits of a time-series process data historian – a software solution that offers high-GRANULARITY, long-term data storage capabilities AS THE BASIS FOR ANALYTICS.

Transform your business and manage risk with INS to protect against cyber threats. Our industrial cybersecurity services are focused on OT networks and OT devices, regardless of the IP protocol in use.

Integrating your ERP system with your manufacturing offers significant benefits. This two-way interface streamlines operations, reduces costs, boosts quality control, and improves traceability – all in real-time.

We provide comprehensive compliance solutions through secure and reliable data collection designed to keep you protected. Data collection solutions are FDA and 21 CFR part 11 compliant.

We help you define, implement, and optimize the use of your machine assets, reduce downtime, and increase productivity.

Our analytics solutions help you identify opportunities to optimize production, improve quality and reduce costs. We are experts at data collection from the manufacturing edge to the cloud and all points in between.

Customer Stories

Ready to scale up your production?