INS3 Learning Center

Case Studies

Empowering Efficiency & Boosting Production with Real-Time Data: The 20% Capacity Leap

Facing the challenge of increasing production by 10-20% for a major customer without quality loss, a cheese processing company, guided by INS3, focused on real-time data use and boosting employee engagement instead of investing heavily in new equipment.

How Algood Foods Dodged Disruption & Saved $100k Daily by Moving Their ERP to the Cloud

Transitioning to a cloud-based Enterprise Resource Planning (ERP) system requires overcoming the challenge of keeping production running smoothly during ERP connectivity issues.

Manufacturing Analytics: A Data-Driven Leap for 10-15% in Quality Boost and Waste Reduction

Examine how Algood addressed its challenges in quality control, scheduling, and waste reduction by adopting data analytics.

Workshops

How We Work

What are the benefits of using a MES Solution?

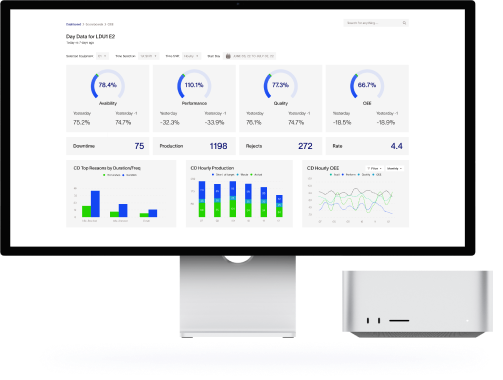

Core MES (Line Monitor) is a packaged application solution that enables improvements in plant profitability, production visibility, and efficiency. If you’re worried about machine downtime and production loss, this solution can help you understand your data and turn that into business decisions. Core MESTM (Line Monitor) is a packaged application solution that enables improvements in plant profitability, production visibility, and efficiency. If you’re worried about machine downtime and production loss, this solution can help you understand your data and turn that into business decisions. Core MES (Line Monitor) is a packaged application solution that enables improvements in.

- Track performance, availability and quality in real-time with dashboards, a large scoreboard and mobile devices

- Eliminate paper and the overhead, errors, and risk associated with it on the plant floor

- Pull down orders easily from SAP and track KPI’s like OEE in real-time

- Digitize production reporting and alert key personnel on variances

- Have a single view and user interface for SAP, production, quality, labor and maintenance

- Integrate to any PLC, CNC, test equipment, scales, RFID, etc., have a

- “black box flight recorder” and enable IoT

- Simplify all confirmations to SAP and do confirmations automatically from machines

Our Blog

GenAI in Manufacturing: Real Results

Unplanned downtime costs manufacturers $50B+ every year—mostly preventable. Traditional SCADA only reacts; AI SCADA predicts and prevents. By learning from your data, it spots issues

When Your Critical Equipment Goes Dark: How AI-Powered SCADA Systems Turn Costly Downtime Into Competitive Advantage

Unplanned downtime costs manufacturers $50B+ every year—mostly preventable. Traditional SCADA only reacts; AI SCADA predicts and prevents. By learning from your data, it spots issues

Digital Twins in Manufacturing: The Complete Guide to Smart Factory Transformation

Smart factories aren’t built overnight. They’re engineered with digital twins. This complete guide shows manufacturers how to leverage IoT-driven digital twin technology to boost efficiency,

MES and Industry 4.0: The Complete Guide to Smart Manufacturing Transformation

The MES market is set to grow at 10.23% CAGR by 2030 — but success isn’t just about adopting new software. MES Industry 4.0 connects

Webinars

GenAI in Manufacturing: Real Results

Unplanned downtime costs manufacturers $50B+ every year—mostly preventable. Traditional SCADA only reacts; AI SCADA predicts and prevents. By learning from your data, it spots issues

When Your Critical Equipment Goes Dark: How AI-Powered SCADA Systems Turn Costly Downtime Into Competitive Advantage

Unplanned downtime costs manufacturers $50B+ every year—mostly preventable. Traditional SCADA only reacts; AI SCADA predicts and prevents. By learning from your data, it spots issues

Digital Twins in Manufacturing: The Complete Guide to Smart Factory Transformation

Smart factories aren’t built overnight. They’re engineered with digital twins. This complete guide shows manufacturers how to leverage IoT-driven digital twin technology to boost efficiency,

MES and Industry 4.0: The Complete Guide to Smart Manufacturing Transformation

The MES market is set to grow at 10.23% CAGR by 2030 — but success isn’t just about adopting new software. MES Industry 4.0 connects

Our Customers

Join the Ranks of these World-Class Industry Manufacturers

Commitment to the highest quality production standards, a broad expertise, and a genuine strive to help our clients achieve their digital transformation.

Ready to scale up your production?