Blog Posts

The AI Disconnect — Why Most Manufacturers Are Nowhere Near ‘Smart’

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

From Excel to MES — Why Mid-Market Manufacturers Can’t Afford to Stay Stuck in Spreadsheets (Even with Some Automation)

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

Modernization Without Chaos — How to Upgrade Legacy Systems While Running at Full Speed

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

The Data Advantage: Why Manufacturing’s AI Success Depends on Quality Data Strategy

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

Deloitte Manufacturing Industry Outlook 2025: Aligning with Results INS3 is Achieving with Manufacturers

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

The Truth About Generative AI in Manufacturing: Enhancement, Not Replacement

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

Smart Manufacturing Technologies: How AI, IIoT, and Data Analytics Transform Factories

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

5 Critical SCADA Integration Mistakes That Cost More Than You Think (Plus Proven Solutions)

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

Why Your MES System Is Your Secret Weapon for Manufacturing AI and Analytics

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

How Edge Analytics is Powering the Next Generation of Manufacturing

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

How MES Software for Manufacturing Streamlines Production and Drives ROI

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

The Power of Manufacturing Analytics: Turning Data into Competitive Advantage

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

How to Choose the Right Smart Manufacturing Technologies for Your Facility?

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

MES and ERP Integration for Smart Manufacturing

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

Industrial Systems Integration: Leveraging AI for Smart Manufacturing Optimization

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

Why Real-Time Production Monitoring Is Critical for Modern Manufacturers

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

How Data Analytics Reduces Downtime in Manufacturing

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

How Modern SCADA Systems Are Transforming Manufacturing Operations

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

The Power of Real-Time Manufacturing Data – MES Connectivity

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

The Digital Transformation Roadmap for Manufacturing Executives

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

SCADA vs. IIoT: Which is Right for Your Manufacturing Operations?

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

Unified Namespace (UNS): The Secret to Seamless Manufacturing Data Integration

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

The Role of AI in Manufacturing: What Every Executive Needs to Know

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

How MES and SCADA Modernization Improve Manufacturing Efficiency

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

Manufacturing Cost Optimization: Using Technology to Drive Profitability

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

The Smart Factory Playbook: A Step-by-Step Guide for Executives

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

From Data to Decisions: How Operations Managers Can Leverage Manufacturing Analytics

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

The Executive Guide to Reducing Downtime with AI and Predictive Analytics

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

How to Future-Proof Your Manufacturing Operations with Real-Time Data

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

The Role of Data Analytics in Reducing Waste and Increasing Efficiency in Manufacturing

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

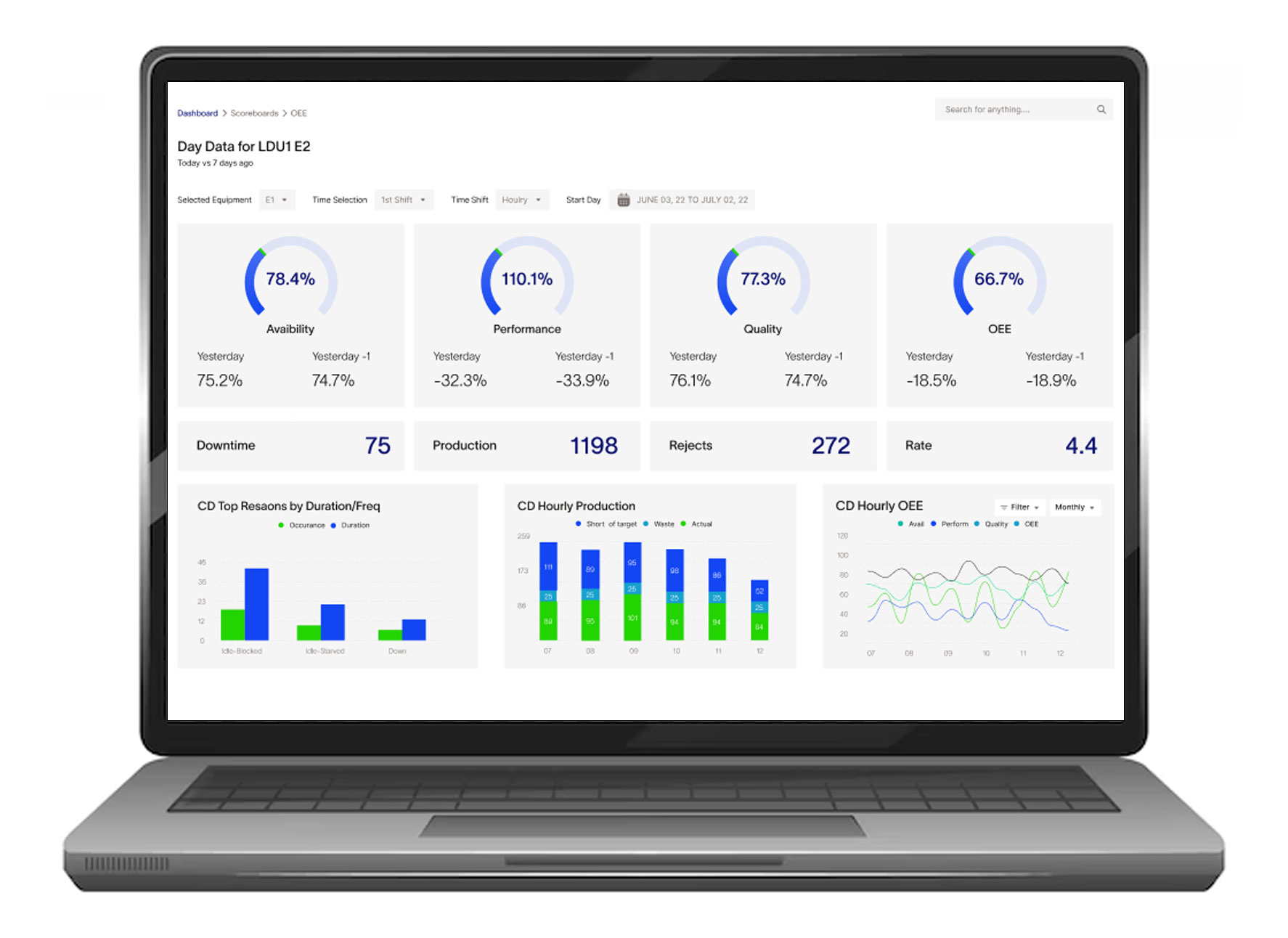

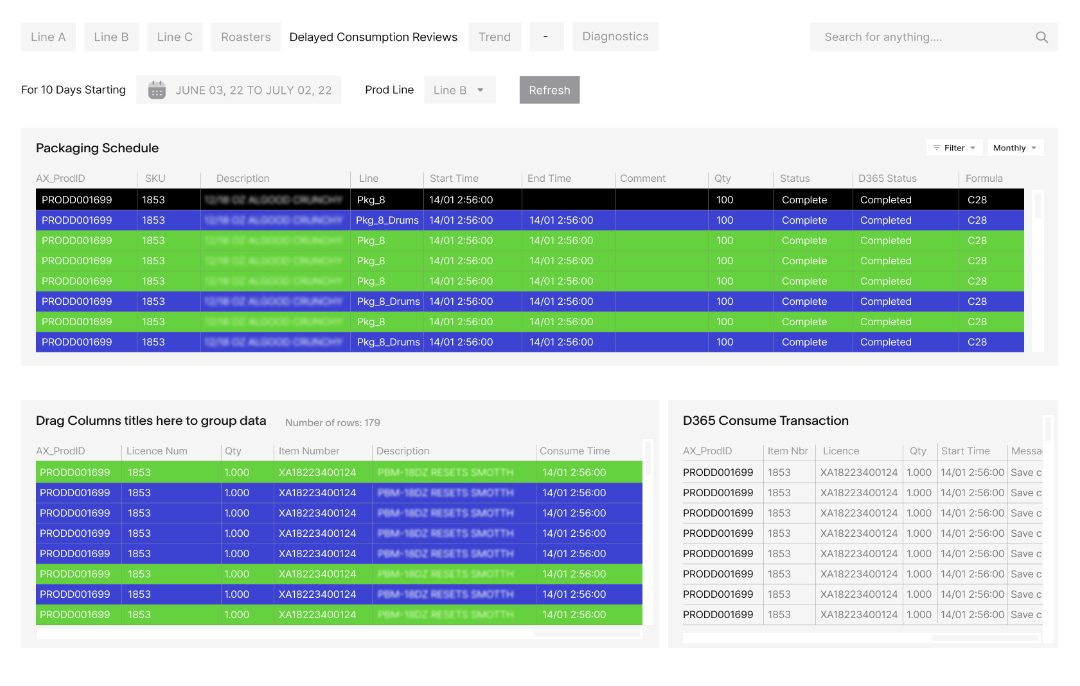

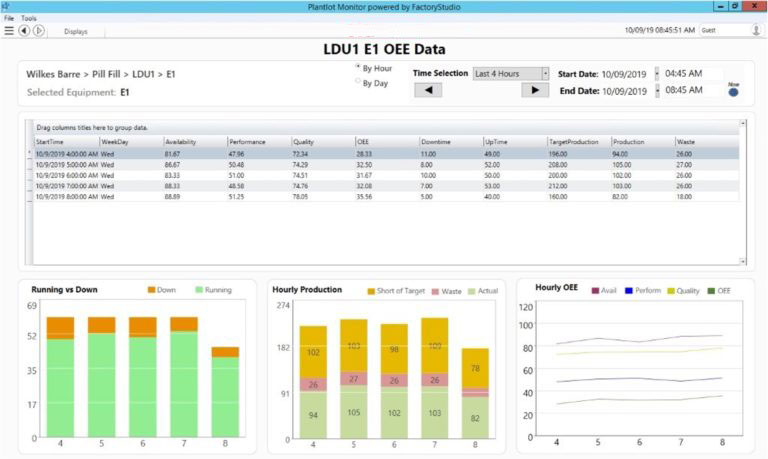

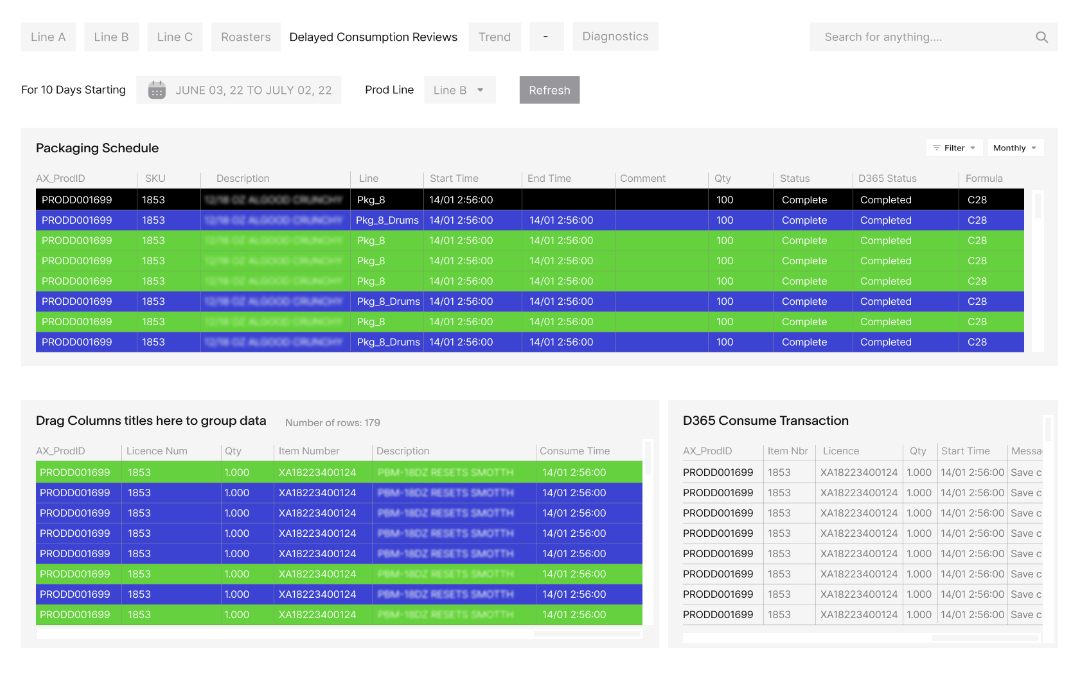

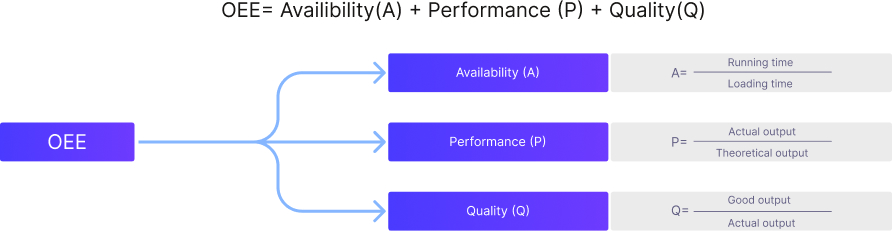

Enhancing Productivity through Data Analysis for Manufacturing: Minimizing Down Time and Enhancing OEE

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

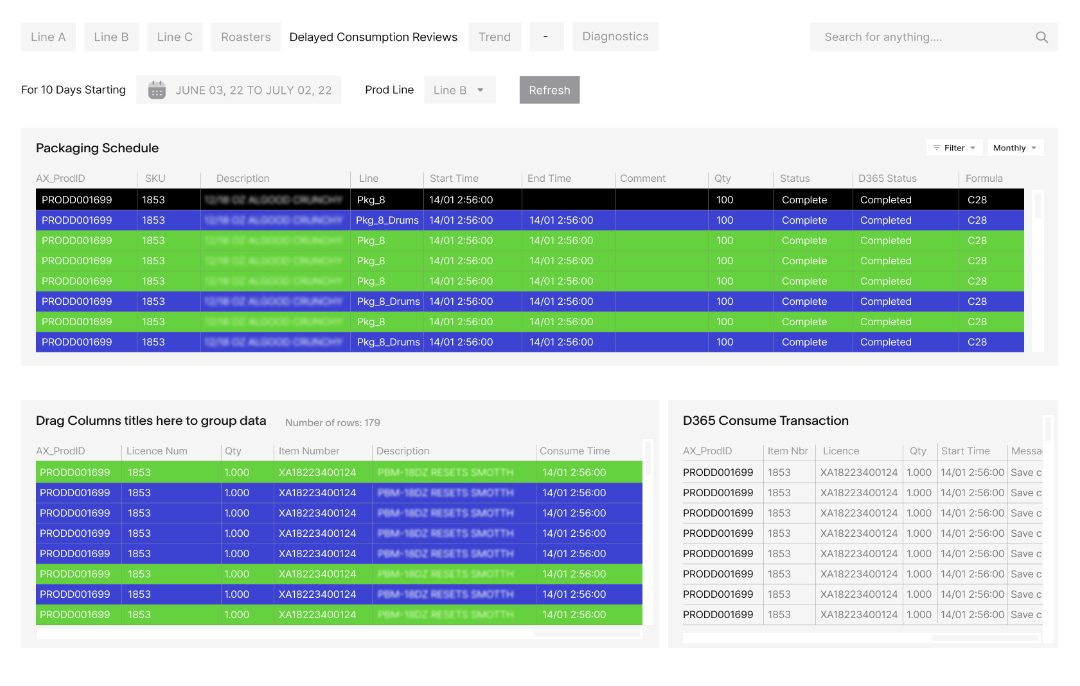

Extend Ignition with MES Software for Manufacturing Intelligence

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

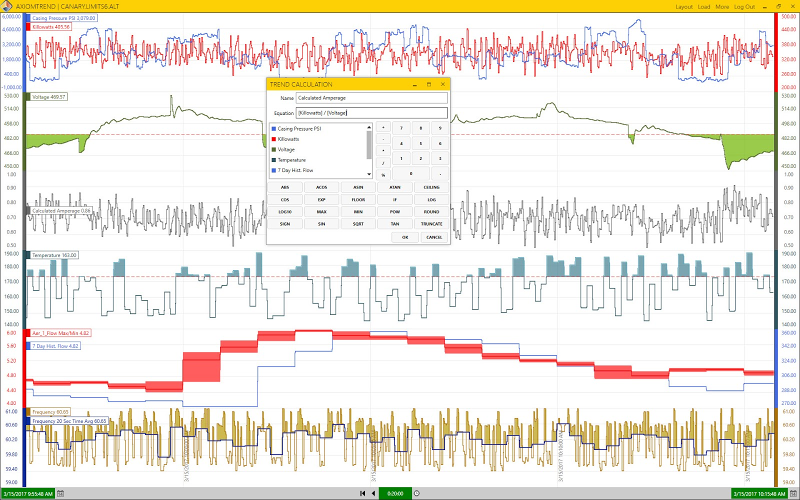

Understanding Data Historians: Streamlining Data Storage and Analysis

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

Maximizing Manufacturing ROI with OEE and Expert System Integration

Maximizing ROI from OEE in manufacturing requires more than just tracking metrics — it demands seamless integration, accurate data, and actionable insights. By partnering with

Maximizing Operational Efficiency: OEE’s Impact Across the Company

Anyone in the operations department is used to looking at numbers every day. But experienced executives can use those numbers and see beyond, to gain

7 Key Things to Implementing MES in Your Manufacturing Operations

If you’re aiming to streamline your manufacturing processes, adopting a Manufacturing Execution System (MES) is the game-changer you need. MES technology bridges the gap between

Unlocking Manufacturing Efficiency with OEE

In the dynamic landscape of manufacturing, maximizing efficiency is paramount for sustainable growth and competitiveness. This is where Overall Equipment Efficiency (OEE) emerges as a

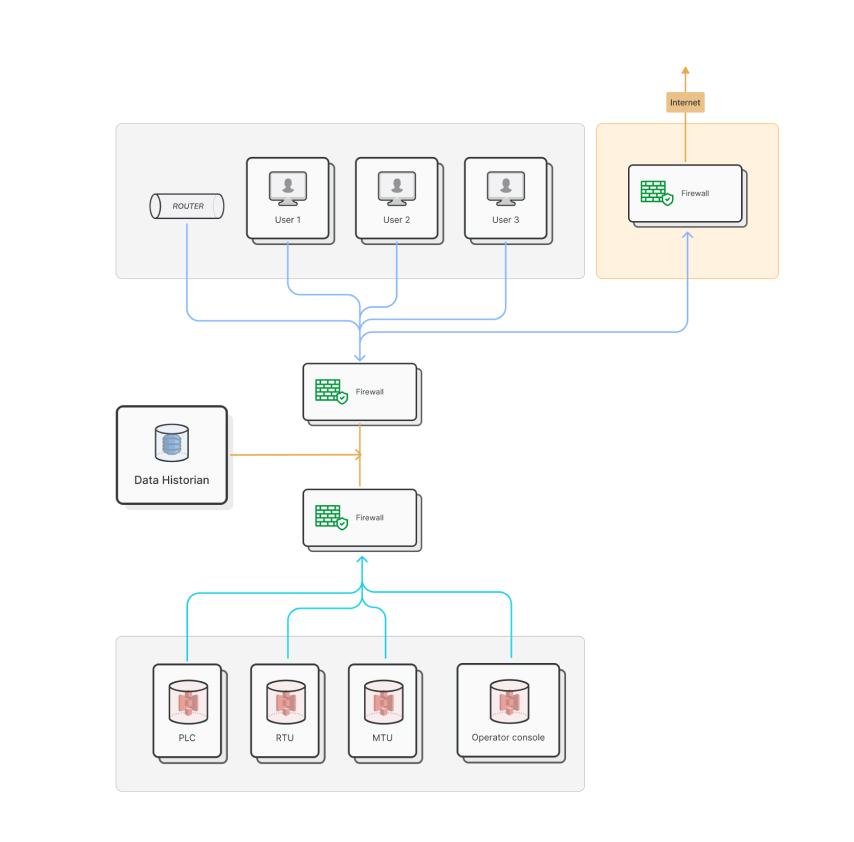

SCADA Security: Protecting Your Industrial Control Systems from Cyber Threats

Supervisory Control and Data Acquisition (SCADA) systems are critical for controlling and monitoring industrial processes. SCADA systems are used in industries such as oil and

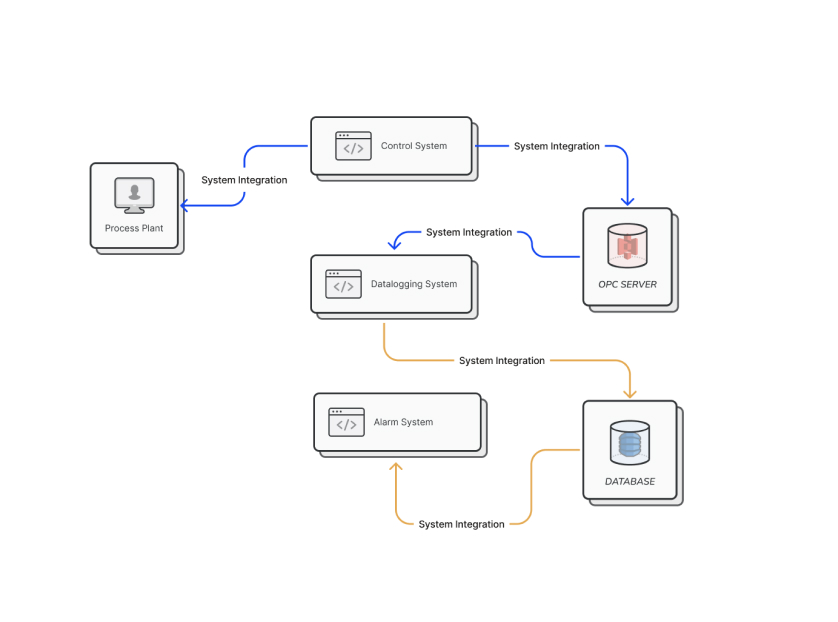

Maximizing Industrial Efficiency: The Power of SCADA System Integration

SCADA stands for Supervisory Control and Data Acquisition. SCADA systems are used in various industries, including the Food & Beverage industry, Food & Beverage, Pharmaceuticals

MES: What is it and how it helps your business

The manufacturing industry has undergone a significant evolution over the past several decades, driven by advances in technology, globalization, and changing customer demands. In the

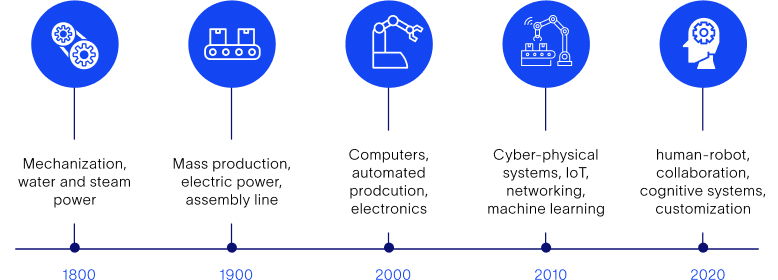

Industry 4.0: Exploring the Fourth Industrial Revolution

In the past few decades, we have witnessed a series of technological advancements that have transformed the way we live, work and communicate. From the

How to Effectively Conduct a Legacy System Integration

Legacy system integration can be a daunting task, but it’s a necessary one for many manufacturers that rely on outdated systems to run their business.

Understanding OEE: The Key to Manufacturing Efficiency

In today’s competitive manufacturing landscape, improving efficiency and productivity is crucial for businesses to remain competitive. One of the key metrics used to measure manufacturing

Agile MES: The Key to Unlocking Smart Manufacturing Success

MES is a computerized system used in manufacturing operations to track and document the transformation of raw materials into finished goods. An MES system typically

Our Customers

Join the Ranks of these World-Class Industry Manufacturers

Commitment to the highest quality production standards, a broad expertise, and a genuine strive to help our clients achieve their digital transformation.

Ready to scale up your production?